Sezvo indasitiri ye semiconductor ichitevera nechisimba sub-2nm process nodes, mukana wekukanganisa kwe mechanical wanyangarika zvachose. Munzvimbo iyi ine matambudziko makuru, kugadzikana kwe process chamber hakusisiri dambudziko rechipiri; ndiyo dambudziko guru rekubudirira. PaZHHIMG, tiri kuona shanduko huru mukuti OEMs yepasi rose inosvika sei pakugadzirisa zvivakwa zve semiconductor capital.

Fizikisi Yokunyarara: Matekiniki Epamusoro Ekudzikisa Kudengenyeka

Mukugadzirwa kwewafer yemazuva ano, kudedera kwaimboonekwa se "ruzha rwekumashure" ikozvino kwava nenjodzi huru. Kungave kuri kutenderera kudiki kubva kuHVAC system yenzvimbo kana kusagadzikana kwemukati kwedanho rekuskena nekukurumidza, simba risingadzorwi rinoshandura zvakananga zvikanganiso zve overlay uye mapatani asina kujeka.

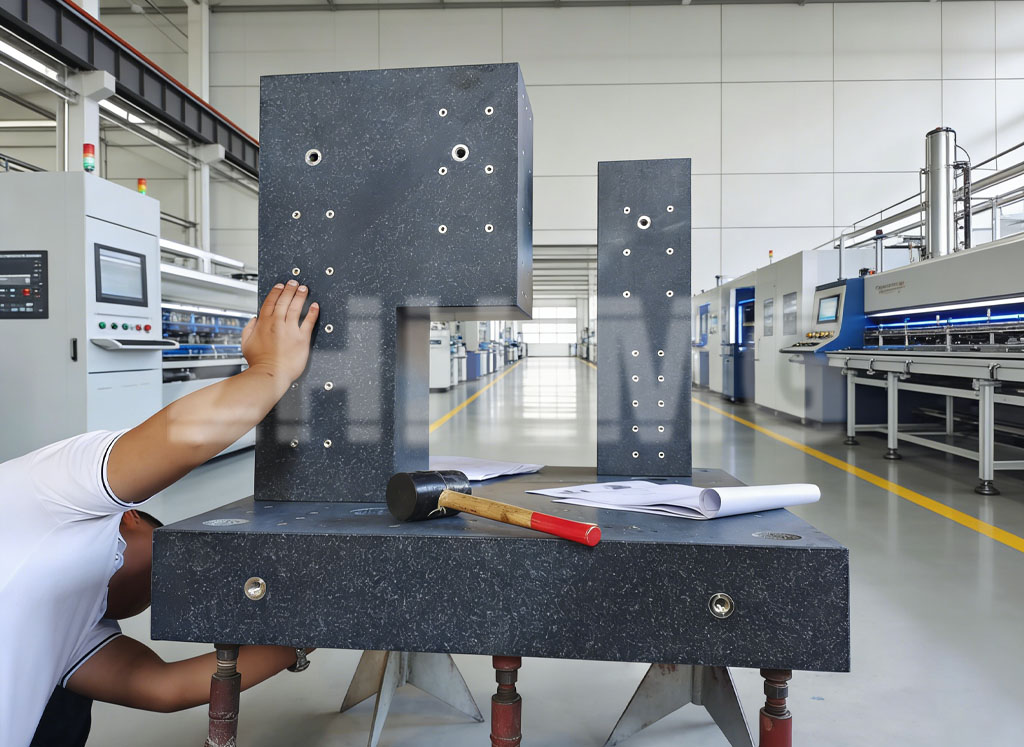

Matekiniki aripo ekudzivirira kudonha kwemvura mukugadzira ma semiconductor akashanduka kuita dhizaini ine mativi akawanda. Kunyange hazvo kuchenesa kusingashande—kushandisa zvinhu zvine huremu hwakawanda senge mineral casting kana precision granite—kuchiri hwaro, tiri kuona kuwedzera kwekubatanidzwa kwekudzivirira kudonha kwemvura.

Masisitimu anoshanda anoshandisa maatomu epiezoelectric uye masensa enguva chaiyo kuti "adzime" vibrations nekugadzira counter-frequency. Zvisinei, kushanda kwemasisitimu anoshanda kunogumira pachiyero chekunyorovesa kwechinhu chepasi. Apa ndipo panonyanya kukosha hunyanzvi hweZHHIMG muzvinhu zvekuvaka zvine damping yakawanda. Nekubatanidza maelektroni anoshanda negranite isina simba kana chigadziko chakabatanidzwa, tinopa "Nzvimbo Yakanyarara" uko nano-positioning inogona kuitika pasina kukanganiswa.

Kukwira kweKufamba Kusina Kukweshana: Tekinoroji yeMhepo Inotakura

Kudiwa kwesimba remagetsi rakawanda kwakasundira mabheyaringi echinyakare kusvika pamiganhu yawo. Kukweshana kunotungamira pakupisa, uye kupisa kunotungamira pakuwedzera kwekupisa—muvengi wekururama. Izvi zvakatungamira pakushandiswa kwakapararira kwetekinoroji yekutakura mhepo yematanho ekururama.

Mabheyaringi emhepo anotsigira mutoro uri pafirimu rakatetepa remhepo yakamanikidzwa, kazhinji kacho ine ukobvu hwema microns mashoma chete. Nekuti hapana kubatana kwemuviri, hapana kukweshana kwesimba (static friction). Izvi zvinobvumira:

-

Kufamba Kusina Hysteresis: Kuve nechokwadi chekuti danho rinodzokera kune nanometer coordinate chaiyo nguva dzese.

-

Kugara Kwekukurumidza: Zvakakosha pakuongorora mashandisirwo akaita seE-beam inspection uko kunyangwe "kuvharwa" kudiki kwebearing yemuchina kunogona kukanganisa mufananidzo.

-

Kugara Nguva Yakareba: Sezvo pasina zvikamu zvinobata, hapana kupera uye hapana kugadzira tunhu tudiki, zvichiita kuti zvive zvakanaka munzvimbo dzekuchenesa dzeClass 1.

KuZHHIMG, tinogadzira nzvimbo dzakatetepa dzegranite dzinoshanda senzira dzinotungamira mabheyaringi aya emhepo. Kuti dzishande nemazvo, nzvimbo idzi dzinofanira kutenderedzwa kusvika pahurefu hwakatarwa muzvikamu zvewavelength yechiedza.

Mafambiro muSemiconductor Capital Equipment: 2026 uye Kupfuura

Sezvatiri kufambira mberi mugore ra2026,mafambiro emidziyo yemari ye semiconductorzvinoratidzwa ne "Mapillars Matatu": Kuchinja, Kugara kwenguva refu, uye Kudzora Kupisa.

-

Kugadzira Mapuratifomu Akagadziriswa: Vagadziri vemapuratifomu vari kutsvaga ma "plug-and-play" base modules. Panzvimbo pekugadzira base itsva yechishandiso chimwe nechimwe, vari kushandisa ZHHIMG precision foundations dzakajairwa dzinogona kugadziriswa kuti dzishandiswe pa lithography, metrology, kana etching.

-

Kutarisira Kupisa: Sezvo chiedza cheEUV (Extreme Ultraviolet) chichiburitsa kupisa kwakanyanya, muchina wacho unofanira kushanda senzvimbo huru yekupisa. Tiri kubatanidza nzira dzakaoma dzekutonhodza zvakananga muzvikamu zvedu zvemineral negranite kuti tirambe tiine delta ye $<0.01^\circ\text{C}$.

-

Kuenderana kweVacuum: Nekufamba kwakawanda kwezvinhu munzvimbo dzine vacuum yakawanda, zvinhu zvinoshandiswa hazvifanirwe kudzima utsi. Kugadziriswa kwedu kwakasarudzika kwegranite neceramic kunoita kuti kuvimbika kwevacuum kusakanganiswa nehwaro hwechivakwa.

Kudyidzana Kwakanaka neZHHIMG

ZHHIMG haisi kambani inogadzira zvinhu chete; isu tiri vashandi pamwe chete muchikamu chekutakura zvinhu. Chivako chedu kuChina chinoshanda pamwe chete nemapoka einjiniya muSilicon Valley neEindhoven kugadzirisa matambudziko akaomarara ekugadzirisa zvinhu muindasitiri iyi.

Nekushandisa nzira dzedu dzekugadzira lapping uye kunzwisisa kwedu kwakadzamamatekiniki ekudzikisa vibration, tinogonesa vatengi vedu kusvitsa miganhu yeMoore's Law. Ungave uri kugadzira chishandiso chechizvarwa chinotevera cheALD (Atomic Layer Deposition) kana kuti wafer prober inokurumidza, hwaro hunotanga neZHHIMG.

Mhedziso

Kushanduka kwekugadzirwa kwema semiconductor inhangemutange inopesana nemitemo yefizikisi. Sezvo indasitiri iri kufambira mberi kusvika muna 2026, kutarisisa pakunyatsoshanda kwemhepo uye damping yepamusoro kuchawedzera. Kuramba uri pamberi pemaitiro aya kunoda hwaro—zvese zviri zviviri uye zvekufananidzira—hwakavakirwa pahunyanzvi uye hunyanzvi hutsva.

Nguva yekutumira: Ndira-26-2026