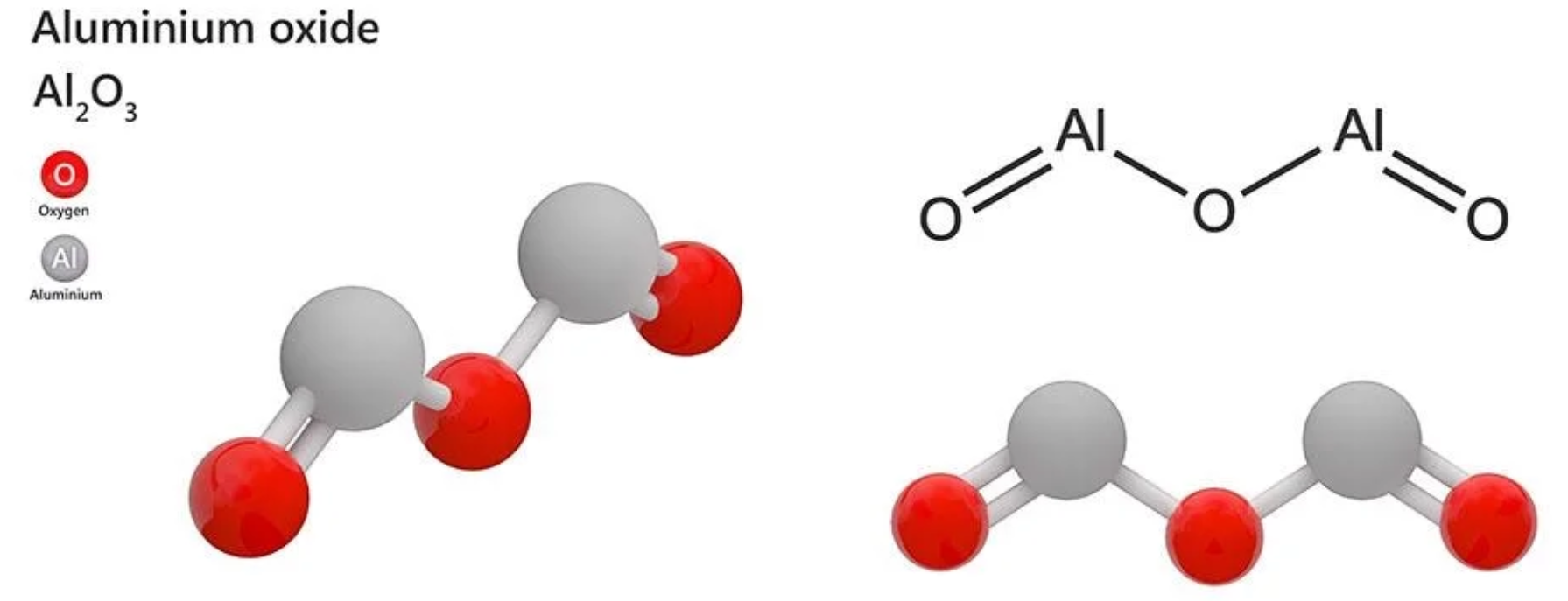

♦Alumina (Al)2O3)

Zvikamu zveceramic zvakagadzirwa neZhongHui Intelligent Manufacturing Group (ZHHIMG) zvinogona kugadzirwa nezvinhu zveceramic zvakachena kwazvo, 92~97% alumina, 99.5% alumina, >99.9% alumina, uye CIP cold isostatic pressing. Kupisa kwakanyanya uye kugadzira nemazvo, kunyatsojeka kwe ± 0.001mm, kutsvedzerera kusvika kuRa0.1, kushandisa tembiricha inosvika 1600 degrees. Mavara akasiyana eceramic anogona kugadzirwa zvichienderana nezvinodiwa nevatengi, zvakaita se: dema, chena, beige, tsvuku yakasviba, nezvimwewo. Zvikamu zveceramic zvakagadzirwa nekambani yedu zvinodzivirira kupisa kwakanyanya, ngura, kupfeka uye kudzivirira kupisa, uye zvinogona kushandiswa kwenguva yakareba munzvimbo inopisa zvakanyanya, vacuum uye gasi rinoparadza.

Inoshandiswa zvakanyanya mumhando dzakasiyana dzemidziyo yekugadzira semiconductor: Mafuremu (ceramic bracket), Substrate (base), Arm/Bridge (manipulator), , Mechanical Components uye Ceramic Air Bearing.

| Zita rechigadzirwa | Kuchena Kwakakwirira 99 Alumina Ceramic Square Tube / Pipe / Rod | |||||

| Index | Chikamu | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Kuwanda kwevanhu | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Kunyudzwa kweMvura | % | <0.1 | <0.1 | 0 | 0 | |

| Kupisa kwakapfava | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Kuoma | Mohs | 7 | 9 | 9 | 9 | |

| Simba Rekukotama (20℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Simba Rinodzvinyirira | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Kushanda Kwenguva Refu Tembiricha | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Kupisa Kushanda Kwakanyanya | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Kuramba kweVhoriyamu | 20℃ | Ω. cm3 | >1013 | >1013 | >1013 | >1013 |

| 100℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300℃ | >109 | >1010 | >1012 | >1012 | ||

Kushandiswa kwesimbi dzesimbi dzealuminium dzakachena zvakanyanya:

1. Inoiswa pamidziyo ye semiconductor: ceramic vacuum chuck, kucheka disc, kuchenesa disc, ceramic CHUCK.

2. Zvikamu zvewafer zvinotakurwa: machucks ekubata wafer, madisc ekucheka wafer, madisc ekuchenesa wafer, macup ekusveta wafer optical inspection.

3. Indasitiri ye LED / LCD flat panel display: ceramic nozzle, ceramic grinding disc, LIFT PIN, PIN rail.

4. Kutaurirana kwemaziso, indasitiri yezuva: machubhu eceramic, tsvimbo dzeceramic, kudhinda madziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emadziro emagetsi ...

5. Zvikamu zvinodzivirira kupisa uye zvinodzivirira magetsi: mabheringi eceramic.

Parizvino, aluminium oxide ceramics inogona kukamurwa kuita ceramics dzakachena uye common ceramics. Iyo high pure aluminium oxide ceramics series inoreva zvinhu zve ceramic zvine anopfuura 99.9% Al₂O₃. Nekuda kwekupisa kwayo kunosvika 1650 - 1990°C uye transmission wavelength yayo ye1 ~ 6μm, inowanzo gadziriswa kuita fused glass pachinzvimbo cheplatinum crucible: iyo inogona kushandiswa se sodium tube nekuda kwelight transmittance yayo uye corrosion resistance kune alkali metal. Muindasitiri yemagetsi, inogona kushandiswa sechinhu chinodzivirira high-frequency yeIC substrates. Zvichienderana nezviri mukati mealuminium oxide, common aluminium oxide ceramic series inogona kukamurwa kuita ceramics 99, ceramics 95, ceramics 90 uye ceramics 85. Dzimwe nguva, ceramics dzine 80% kana 75% yealuminium oxide dzinoiswawo mu common aluminium oxide ceramic series. Pakati pazvo, zvinhu zve 99 aluminium oxide ceramic zvinoshandiswa kugadzira chubhu yefurnace inodziya zvakanyanya, inodzivirira moto uye zvinhu zvakakosha zvinodzivirira kupfekwa, zvakaita semabheringi e ceramic, zvisimbiso zve ceramic uye mavharuvhu. Zvisimbiso zve aluminium 95 zvinonyanya kushandiswa sechinhu chinodzivirira kupfekwa chinodzivirira ngura. Zvisimbiso zve 85 zvinowanzo sanganiswa mune zvimwe zvinhu, nokudaro zvichivandudza mashandiro emagetsi uye simba remakanika. Zvinogona kushandisa molybdenum, niobium, tantalum nezvimwe zvisimbiso zvesimbi, uye zvimwe zvinoshandiswa semidziyo yemagetsi yekuputira.

| Chinhu Chemhando Yepamusoro (Kukosha Kunomiririra) | Zita rechigadzirwa | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Kuumbwa Kwemakemikari Chigadzirwa Chinobvisa Sodium Yakawanda | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Lol | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Dhayamita yepakati nepakati (MT-3300, nzira yekuongorora nelaser) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| Saizi yekristaro α | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Kuumbwa kweHuremu** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Kuwanda kweSintering** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Kuderera Kwehuwandu hweSintering Line** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO haibatanidzwi mukuverengwa kwekuchena kweAl₂O₃.

* Hapana upfu hwekuyera 29.4MPa (300kg/cm²), tembiricha yekudziya moto ndeye 1600°C.

AES-11 / 11C / 11F: Wedzera 0.05 ~ 0.1% MgO, kugona kwayo kunoshanda zvakanaka, saka inoshanda kune aluminium oxide ceramics ine kuchena kweanopfuura 99%.

AES-22S: Inoratidzwa nekuwanda kwekugadzira zvinhu uye mwero wakaderera wekuderera kwemutsetse wekupisa, inoshanda kune zvigadzirwa zvakakura zvine mativi akakodzera.

AES-23 / AES-31-03: Ine huremu hwakanyanya, thixotropy uye viscosity yakaderera pane AES-22S. yekutanga inoshandiswa kugadzira zviumbwa zvesimbi nepo yekupedzisira ichishandiswa sechinoderedza mvura yezvinhu zvinodzivirira moto, zvichiwedzera kufarirwa.

♦Maitiro eSilicon Carbide (SiC)

| Hunhu Hwakajairika | Kuchena kwezvikamu zvikuru (wt%) | 97 | |

| Ruvara | Nhema | ||

| Kuwanda (g/cm³) | 3.1 | ||

| Kunyudzwa kwemvura (%) | 0 | ||

| Hunhu hweMichina | Simba rekuchinjika (MPa) | 400 | |

| Modulus yechidiki (GPa) | 400 | ||

| Kuomarara kweVickers (GPa) | 20 | ||

| Hunhu hwekupisa | Tembiricha yepamusoro yekushandisa (°C) | 1600 | |

| Chiyero chekuwedzera kwekupisa | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Kufambisa kwekupisa (W/mxK) | 130 110 | ||

| Kuramba kupisa ΔT (°C) | 300 | ||

| Hunhu hweMagetsi | Kudzivirira kwevhoriyamu | 25°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectric constant | 10GHz | - | |

| Kurasikirwa kweDielectric (x 10-4) | - | ||

| Q Factor (x 104) | - | ||

| Voltage yekuputsika kwemagetsi (KV/mm) | - | ||

♦Silikoni Nitride Ceramic

| Zvinhu | Chikamu | Si₃N₄ |

| Nzira yekuchenesa | - | Kumanikidzwa kweGasi kwakadzimwa |

| Kuwanda kwevanhu | g/cm³ | 3.22 |

| Ruvara | - | Gireyi Rakasviba |

| Mwero weKunyudzwa kweMvura | % | 0 |

| Modulus Mudiki | Gpa | 290 |

| Kuomarara kwaVickers | Gpa | 18 - 20 |

| Simba Rinodzvinyirira | Mpa | 2200 |

| Simba Rekukombama | Mpa | 650 |

| Kufambisa kwekupisa | W/mK | 25 |

| Kuramba Kupisa Kwekupisa | Δ (°C) | 450 - 650 |

| Kupisa Kunoshanda Kwakanyanya | °C | 1200 |

| Kuramba kweVhoriyamu | Ω·cm | > 10 ^ 14 |

| Dielectric Constant | - | 8.2 |

| Simba reDielectric | kV/mm | 16 |