Mumakamuri akanyarara ema calibration laboratories, semiconductor cleanrooms, uye aerospace metrology suites, shanduko yakanyarara iri kuitika. Hazvitungamirirwi nesoftware kana masensa chete—asi nezvinhu chaizvo zvinoumba hwaro hwekuyera pachazvo. Pamberi pekuchinja uku pane zvishandiso zvekuyera zveceramic zvepamusoro, zvinosanganisira ultra-stable ceramic air straight ruler uye exceptionally rigid high precision silicon-carbide (Si-SiC) parallelepiped uye square. Izvi hazvisi zvishandiso chete; zvinopa simba renguva itsva apo kugadzikana, kudzokorora, uye thermal neutral hazvigone kutaurirana.

Kwemakore anopfuura makumi mashanu, granite nhema yainyanya kushandisa hunyanzvi hwayo hwekuita zvinhu. Kunyorova kwayo kwechisikigo, kuwedzera kupisa kwakaderera, uye kusatsetseka kwakanaka kwakaita kuti ive chinhu chinodiwa pakugadzira mapuratifomu epamusoro, masikweya, uye mipendero yakatwasuka. Asi sezvo maindasitiri achikwira mukusawirirana kwe sub-micron uye kunyange nanometer-scale - kunyanya mu semiconductor lithography, space optics, uye quantum computing - miganhu yegranite yave kuoneka zvakanyanya. Inorema, inogona kubatwa ne micro-chipping kana yakabatana kakawanda, uye, pasinei nemukurumbira wayo, ichiri kuratidza kudonha kwenguva refu pasi pemutoro kana kushanduka kwezvakatipoteredza.

Shandisa zviumbwa zvesimbi zvakagadzirwa nesimbi: kwete zviumbwa zvesimbi zvinogara zvichingoonekwa, asi zvinhu zvakasimba, zvakafanana, zvinoshanda zvakanyanya zvakagadzirwa pasi pekupisa kwakanyanya uye kumanikidzwa. Pakati peizvi, mapoka maviri anonyanya kushandiswa pakuongorora simbi: high-purity alumina (Al₂O₃) uye reaction-bonded silicon carbide (Si-SiC). Kunyange zvazvo zvose zvichipa kuvandudzwa kukuru pane zvinhu zvechinyakare, zvinoshanda mabasa akasiyana—uye pamwe chete, zvinomiririra mugumo wezvinogoneka mukuongorora simbi.

Semuenzaniso, tora ceramic air straight ruler. Yakagadzirirwa kushandiswa nematanho emhepo kana optical interferometers, chishandiso ichi chinoda kutwasuka kwakakwana, huremu hushoma, uye hapana kudonha kwekupisa.vatongi vedongo—yakagadzirwa kuti ive yakati sandara uye yakatwasuka mukati me ±0.5 µm pamusoro pe 500 mm uye yakapetwa kusvika pakukora pasi peRa 0.02 µm—inoita izvozvo chaizvo. Kurema kwavo kushoma (~3.6 g/cm³) kunoderedza kusagadzikana mumasisitimu ekuyera anochinja-chinja, nepo hunhu hwavo husina simba remagineti, husingafambise mhepo hunobvisa kupindira munzvimbo dzine hunyanzvi hwemagetsi kana magineti. Muzvishandiso zvekuongorora wafer kana laser tracker calibration setups, uko kunyangwe micron yebow inogona kukanganisa mhedzisiro, ceramic air straight ruler inopa reference yakagadzikana, isina simba inoramba iri yechokwadi mukuchinja kwekushisa uye mashandiro ekushanda.

Asi kana paine kuomarara kwakanyanya uye thermal conductivity zvinodiwa—sekunge mu space telescope mirror alignment kana high-power laser cavity metrology—mainjiniya anoshandisa high precision silicon-carbide (Si-SiC) parallelepiped uye square components. Si-SiC ndeimwe yezvinhu zvakasimba zvinozivikanwa, ine Young's modulus inodarika 400 GPa—inopfuura katatu kupfuura yesimbi—uye thermal conductivity inokwikwidzana nealuminium. Chinokosha ndechekuti, coefficient yayo yekuwedzera thermal (CTE) inogona kugadzirwa kuti ienderane neyemagirazi e optical kana silicon wafers, zvichiita kuti near-zero differential expansion expansion mu hybrid assemblies. Si-SiC square inoshandiswa se master reference mu EUV lithography tool haingori muchimiro chayo—icharamba ichirwisa kukanganiswa kubva mu localized heating kana vibration.

Chinoita kuti kubudirira uku kukwanisike hakusi chete zvinhu, asi kugona kugadzira zvishandiso zvekuyera zveceramic. Semuenzaniso, kugadzira Si-SiC nemazvo kunoda mavhiri ekukuya madhaimani, mapuratifomu eCNC e sub-micron, uye maitiro ekubatanidza machira akawanda anoitwa munzvimbo dzinodzorwa nekupisa. Kunyangwe kushushikana kudiki kunobva mukupiswa kusina kunaka kunogona kutungamira kukugadzirisa mushure mekugadzira. Ndosaka vagadziri vashoma vepasi rose vanosanganisira kugadzira zvinhu, kugadzira nemazvo, uye metrology yekupedzisira pasi pedenga rimwe chete—kugona kunoparadzanisa vagadziri vechokwadi vemetrology kubva kune vatengesi veceramic.

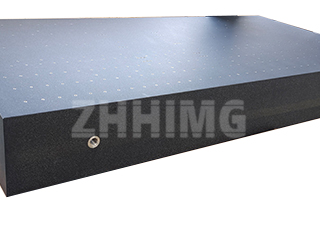

KuZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), kubatanidzwa uku kwakamira ndiko kwakakosha pabasa redu. Zvishandiso zvedu zvekuyera zveceramic—kusanganisira ceramic air straight ruler models dzakabvumidzwa neDIN 874 Grade AA uye high precision silicon-carbide (Si-Si-C) parallelepiped uye square artifacts dzinoteverwa nePTB neNIST standards—zvinogadzirwa muISO Class 7 cleanrooms uchishandisa proprietary sintering and finishing protocols. Chikamu chega chega chinoongororwa zvizere, CMM verification of geometric tolerances (flatness, parallelism, perpendicularity), uye surface integrity testing isati yatumirwa. Mhedzisiro yacho i reference-grade artifact isingangosviki pane zvinodiwa—inodarika nguva dzose muma batches.

Kudiwa kwekushanda kwakadaro kuri kuwedzera. Mukugadzira semiconductor, EUV uye high-NA lithography systems zvinoda kuti zvimiro zve alignment zvigadzikane kusvika mukati memakumi e nanometers pamusoro pemamita-scale—zvisingagoneke pasina Si-SiC's thermal-mechanical synergy. Mundege, mabhenji e satellite optical akagadzirwa ne ceramic references anovimbisa kugadzikana pa-orbit pasinei nekupisa kwakanyanya. Kunyangwe munzvimbo dziri kubuda dzakadai se gravitational wave detection kana atomic clock development, uko kugadzikana kwe picometer-level kunokosha, ceramic uye Si-SiC metrology artifacts zviri kuva zvisingakoshi.

Zvakakosha kuti zvishandiso izvi zvinotarisawo kuchengetedzeka uye mutengo wese wekuva muridzi. Kunyange hazvo mari yekutanga mu silicon-carbide parallelepiped yakanyatsogadzirwa ichigona kupfuura granite equivalent, hupenyu hwayo hwekushanda hunogona kureba ka5-10 munzvimbo dzinoshandiswa zvakanyanya. Haidi mafuta, inodzivirira zvese zvinonyungudutsa uye plasma, uye haimbodi kugadziriswazve nekuda kwekunwa hunyoro—kusiyana nesimbi yakakandwa kana mamwe magranite. Kune vatariri vemhando yepamusoro vanoshanda pasi peAS9100, ISO 13485, kana SEMI standards, kuvimbika uku kunoshandura zvakananga kuderedzwa kwenguva yekushanda, kuwanikwa kweongororo shoma, uye chivimbo chikuru chevatengi.

Uyezve, runako uye kushanda zvakanaka kwezviridzwa izvi hazvifanirwe kufuratirwa. Sikweya yeSi-SiC yakaposhwa inopenya nerunako rwesimbi asi inorema zvishoma pane simbi. Rura re ceramic air straight rinonzwa rakasimba asi rinosimudza nyore nyore—rakanakira kuongororwa nemaoko munzvimbo dzakamanikana. Hunhu uhwu hunotarisa vanhu hunokosha mumarabhoritari chaiwo epasi rose uko ergonomics uye nyore kushandisa zvinopesvedzera mashandiro ezuva nezuva.

Saka, zvishandiso zvekuyera zveceramic zviri kutsanangura patsva kunyatsojeka kwakanyanya here? Mhinduro iri mudata—uye murunyorwa rwuri kukura rwevatungamiriri vepasi rose vava kuzvitsanangura sezvinodiwa. Kubva kumasangano emetrology enyika ari kusimbisa mwero wehurefu hwechizvarwa chinotevera kusvika kune vatengesi veTier 1 vanosimbisa zvikamu zveEV drivetrain, shanduko yacho yakajeka: kana kusava nechokwadi kuchifanira kuderedzwa, mainjiniya anovimba nezvigadzirwa zveceramic zvakagadzirwa nemainjiniya.

Uye sezvo maindasitiri achienderera mberi nerwendo rwavo rusingaperi rwekudzora chiyero chemaatomu, chokwadi chimwe chete chinova chisingarambiki: remangwana rekuyera harizove rakavezwa kubva padombo kana kuumbwa nesimbi. Richapiswa, kukuyiwa, uye kupukutwa neceramic—uye silicon carbide.

ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) inyanzvi inozivikanwa pasi rose mukugadzira mhinduro dzemetrology dzeceramic nesilicon-carbide dzakarurama. Iine hunyanzvi mukugadzira zvishandiso zvekuyera zveceramic, ceramic air straight ruler, uye high precision silicon-carbide (Si-SiC) parallelepiped uye square components, ZHHIMG inopa zvigadzirwa zvemhando yepamusoro zve semiconductor, aerospace, defense, uye scientific research applications. Ichitsigirwa ne ISO 9001, ISO 14001, uye CE certifications, zvigadzirwa zvedu zvinovimbwa nemabhizinesi etekinoroji anotungamira pasi rese. Ongorora portfolio yedu yepamusoro yemetrology pawww.zhhimg.com.

Nguva yekutumira: Zvita-05-2025