Munyaya ye semiconductor wafer grooving, kunyatsoita zvinhu ndiko kunobatsira zvikuru. Granite base isingawanzoitiki inogona kuunza shanduko huru mukushanda kwemidziyo yegrooving! Ndeipi "masimba makuru" ainoviga? Sei zvichinzi kusarudza granite base chaiyo zvinoreva kuti wabudirira pakati? Nhasi, tichakuratidza zvakadzama!

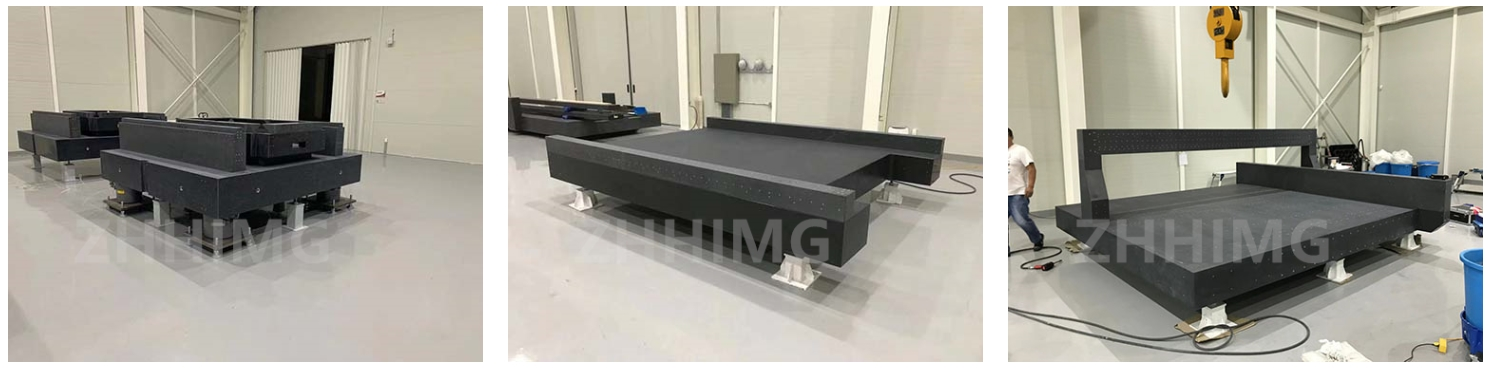

I. Simba Rechisikigo: "Mabhenefiti Matatu" eGranite

Kudzivirira kudengenyeka kwenyika kwakasimba sezvakaita Mount Tai

Granite ine huwandu hwakakura hunosvika 2,800-3,100 kg/m³, uye chimiro chayo chakakora se "nhare yematombo". Munzvimbo ine vibration yakawanda ye wafer grooving (michina inoyerera kanopfuura zana paminiti), inogona kunwisa simba rinodarika 90% re vibration, sekunge ichipa michina "teknolojia nhema inobata kuvhunduka"! Data rakayerwa kubva kune imwe fekitori yemachipisi rinoratidza kuti mushure mekushandisa granite base, jitter amplitude ye grooving cutter head yakadzikira kubva pa15μm kusvika pa3μm, uye mipendero yema micro-grooves akavezwa yakatsetseka segirazi.

2. "Muviri unodzivirira kupisa" Usatya kusiyana kwekupisa

Zvinhu zvakajairika "zvinokura uye zvinokanganisika" kana zvadziiswa uye "zvinogumira uye zvinokanganisika" kana zvatonhodzwa, asi thermal expansion coefficient yegranite yakaderera se4-8×10⁻⁶/℃, inova 1/5 chete yesimbi! Kunyangwe tembiricha iri muworkshop ikachinja zvakanyanya ne10℃ mukati memaawa makumi maviri nemana, deformation yayo iri pasi pe0.01mm uye inogona kupotsa yaregeredzwa. Izvi zvinoreva kuti pasinei nekuchinjwa kwemasikati neusiku kana kushanda kwenguva refu uye kugadzirwa kwekupisa kwemidziyo, granite base inogona kuchengetedza nzvimbo yeslot "isina kufamba" nguva dzese.

3. Kuramba kusakara kusingaparare

Kuomarara kwegranite kwaMohs kunosvika 6 kusvika ku7, kwakafanana nekwematombo equartz, uye kuramba kwayo kupfeka kwakapetwa katatu kupfuura kwesimbi yakajairika! Pasi pekukweshana kwenguva refu kwewafer grooving, pamusoro pechigadziko hahuna kupera simba. Mushure mekunge imwe foundry yashandisa mabhesi egranite kwemakore mashanu, kutsetseka kwacho kwakaramba kuri mukati me ±0.5μm/m pakuongororwa, uye kururama kwekukwesha kwakaramba kwakafanana, zvichichengetedza mari yakawanda yekuenzanisa michina uye yekutsiva.

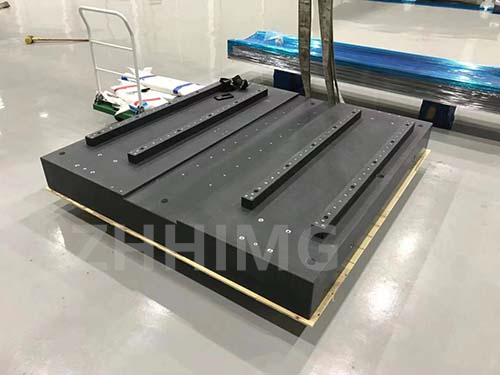

Ii. Kugadziriswa Kwakarurama: Granite Inosangana Sei Nezvinodiwa Zvakasiyana zveGrooving?

Chiitiko 1: Kukwesha zvishoma (maburi madiki ari pasi pe10μm)

Chinodiwa: Kugara kwakadzikama

Zvakanakira granite: Kuburikidza nekushandisa tambo dzekubatanidza dzine mativi mashanu nemazvo, hutete hunogona kudzorwa mukati me ±0.5μm/m, zvinoreva kuti pakureba kwemita imwe chete, kukanganisa kwekukwirira kutete ka200 pane bvudzi remunhu! Iva nechokwadi chekuti daro riri pakati pemusoro wekucheka grooving newafer rinogara rakanyatsojeka, uye kukanganisa kwehupamhi hwema micro-grooves akavezwa hakupfuuri ±0.1μm.

Chiitiko chechipiri: Kugadzira zvinhu zvinokurumidza kugadzirwa

Zvinodiwa: Kushanda kweSuper shock absorption

Zvakanakira granite: Hunhu hwayo hwekunyorovesa mukati hunogona kukurumidza kuderedza kudedera kwemidziyo. Mushure mekunge imwe fekitori yatanga mabhesi egranite, kumhanya kwekugadzira kwakawedzera ne40%, uye mwero wegoho wakakwira kubva pa85% kusvika pa96%, zvichiita kuti goho rekugadzira rive rakapetwa kaviri!

Chiitiko chechitatu: Kugadzirisa nzvimbo yakaoma (Kupisa kwakanyanya/ngura)

Zvinodiwa: Kudzivirira kupisa kwakanyanya uye kuramba ngura

Zvakanakira granite: Kugadzikana kwemakemikari kwakasimba zvikuru, kunodzivirira ngura neacid nealkali; Ine coefficient yakaderera yekuwedzera kwekupisa uye haizokanganisike kunyangwe pakupisa kwakanyanya kwenzvimbo (150℃) panguva yekucheka nelaser. Hwaro hwegranite hunoshandiswa mune imwe rabhoritari ine corrosive grooving solution hwave huchishandiswa kwenguva refu kwemakore matatu, uye pamusoro pehwaro hunoramba hwakakwana.

Iii. Ungasarudza sei "Gwaro reGranite remhando yepamusoro"?

Tarisa huwandu hwemagranite: Granite ine huwandu hwe ≥2800kg/m³ ine chimiro chakaoma.

Tarisa zvitupa: Iva nechokwadi chekuti wagamuchira zvitupa zvine mvumo zvakaita seISO 9001 neCNAS kuti uve nechokwadi chekuti zvine mhando.

Ruzivo rwekusimbisa: Mugadziri anofanirwa kupa mishumo yekuyedza pamusoro pehuwandu hwekuwedzera kwekupisa (< 8×10⁻⁶/℃) uye kutsamira (± 0.5μm/m).

Kuedza panzvimbo: Bata pasi. Ruzha rwakajeka runoratidza kuti hapana mitswe mukati. Kana nzvimbo yekubata yakatsetseka segirazi, zvinoratidza kunyatsogadzirisa kwakasimba.

Mhedziso: Sarudza granite chaiyo uye ukunde hafu yehondo mu grooving!

Kubva pakusagadzikana kwekushomeka, kusapisa kusvika pakusapera, hwaro hwegranite, ne "runako rwayo rwechisikigo" uye "simba rakasimba", hwave mubatsiri wepamusoro wemidziyo yekugocha wafer. Munguva yanhasi yekugadzira semiconductor inotevedzera nanoscale chaiyo, hwaro hwegranite hwemhando yepamusoro hausi kungodyara mumidziyo chete asiwo vimbiso yenguva refu yekushanda zvakanaka kwekugadzira uye kunaka kwechigadzirwa!

Nguva yekutumira: Chikumi-17-2025