Mubasa rekugadzira PCB (Printed Circuit Board), kunyatsorongeka kwekuchera kunosarudza zvakananga mashandiro emagetsi uye mwero wekubereka kwebhodhi redunhu. Kubva kumachipisi efoni kusvika kumabhodhi edunhu remuchadenga, kururama kwenzvimbo yega yega ye micron-level kwakakosha pakubudirira kana kutadza kwechigadzirwa. Mabhesi egranite, ane hunhu hwawo hwakasiyana uye zvakanakira chimiro, ari kuva "mubatsiri wegoridhe" wemidziyo yekuchera yePCB, zvichitungamira kunyatsorongeka kweindasitiri kusvika pakukwirira kutsva.

I. Kubatsira Kwazvinoita: Kushanda zvakanaka kunoita kuti pave neunyanzvi hwakakwana

Kugadzikana kwakanyanya kwekupisa

Munguva yekuboorwa kwePCB, kupisa kunokonzerwa nekutenderera nekukurumidza kwe drill bit kunogona kusvika 60-80℃. Kuwedzera kwezvinhu zvesimbi zvakajairika nekuda kwekupisa kunogona kukonzera kuti nzvimbo yekuboorwa ichinje. Coefficient yekuwedzera kwekushisa kwegranite inongova 4-8×10⁻⁶/℃, inova 1/5 chete yesimbi. Izvi zvinoreva kuti kunyangwe tembiricha yemhepo ikachinja zvakanyanya, deformation ye granite base inogona kuregeredzwa. Mushure mekunge mumwe mugadziri we circuit board atora granite base, kukanganisa kwenzvimbo yekuboorwa kwakaderedzwa kubva pa ±50μm kusvika pa ±10μm, zvichivandudza zvakanyanya kushanda kwemagetsi kwe circuit board.

2. Kushanda nesimba kwekudengenyeka kwenyika

Kudengenyeka kwemuchina wekuboorera une mavhiri akawanda paminiti kunogona kukanganisa kumira kwegomba rekuboorera, zvichikonzera kutsauka kwedhayamita yegomba. Hunhu hwekunyorovesa huri mukati megranite hunoita kuti ikwanise kunwisa anopfuura 90% yekudengenyeka kwemidziyo (20-50Hz). Data rakayerwa rinoratidza kuti mushure mekuisa hwaro hwegranite, amplitude yegomba rekuboorera yakaderera kubva pa15μm kusvika pa3μm, uye kukosha kweRa kwekukombama kwemadziro egomba rakaboorerwa kwakaderera ne60%, zvichideredza zvakanyanya matambudziko egomba rekuboorera.

3. Kuramba kupfeka kwenguva refu

Kuboora PCB ibasa rinoitwa kakawanda uye rinoda simba guru rekudzivirira kupfekwa kwepasi. Granite ine kuomarara kweMohs kwe6 kusvika ku7 uye kuramba kwayo kupfekwa kwakapetwa katatu kupfuura simbi yakajairika. Fekitori hombe yePCB yagara ichishandisa mabhesi egranite kwemakore matatu. Kupfekwa kwepasi kuri pasi pe0.01mm. Kana tichienzanisa nemabhesi esimbi, kutenderera kwekutsiva kunowedzerwa kaviri, zvichideredza mutengo wekugadzirisa michina.

Ii. Kuvandudzwa Kwemaitiro: Dhizaini yakagadzirirwa inovandudza kushanda zvakanaka kwekugadzira

Mabhesi egranite emazuva ano, kuburikidza nekugadzirwa kwakanyatsogadzirwa uye zvivakwa zvitsva, zvinowedzera kukosha kwekushandiswa kwawo:

Kugadziriswa kwepuranar kwakanyatsogadzirwa: Nekushandisa tekinoroji yekudzora nhamba yekubatanidza mativi mashanu, kusimba kwechigadziko kunodzorwa mukati me ±0.5μm/m, zvichipa nzvimbo yepamusoro-soro yekutarisa michina yekuboorera uye kuve nechokwadi chekuti kukanganisa kwe drill bit kuri pasi pe 0.01°.

Chimiro chekunyudzwa kwehuchi: Dhizaini yemukati mehuchi inoumba gomba rakazvimiririra, zvichiita kuti simba rekuzununguka ridzikire zvakanyanya, uye rakakodzera zvikuru kugadziriswa kwemaburi madiki e0.1mm kana pasi.

Nzira dzekutonhodza mvura dzakagadzirwa kare: Pamidziyo yekuboora ine simba guru, sisitimu yekutonhodza mvura ine chiteshi chidiki yakavakirwa mukati inoiswa kuti idzore musiyano wetembiricha pamusoro pechigadziko mukati me ±0.5℃, zvichibvisa zvachose njodzi yekushanduka kwekupisa.

Kurongeka kweT-slot Yakagadzirirwa: Nzvimbo yekupatsanura T-slot uye kunyatsorongeka (± 0.01mm) zvinogadziriswa zvichienderana nemuenzaniso wemuchina wekuboorera kuti zvikwanise kuiswa nekukurumidza uye kuiswa kwemidziyo, zvichideredza nguva yekuiswa kwemudziyo mumwe chete ne70%.

Iii. Humbowo hweMaindasitiri: Kuvandudzwa Kunooneka Kwekushanda Nesimba

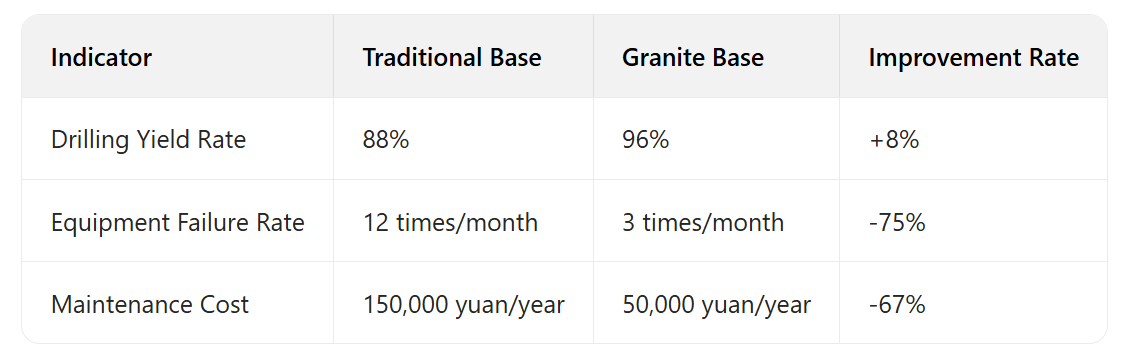

Mushure mekunge mumwe mugadziri wePCB anotungamira atanga mabhesi egranite, data rekugadzira rayo rakavandudzika zvikuru:

Chinonyanya kukosha ndechekuti, hwaro hwegranite hwakabatsira mabhizinesi kupinda mumatambudziko ehunyanzvi, kubudirira kuita maodha emakomba madiki ane 0.2mm kana pasi, uye kuvhura misika ine kukosha kwakanyanya.

Iv. Mabhenefiti Anogarika: Sarudzo yakanaka yekugadzira zvinhu zvakasvibira

Granite idombo rechisikigo risina makemikari ekuputira uye harina VOCs, zvichisangana nezvinodiwa zveRoHS zvekuchengetedza nharaunda. Nguva yayo yakareba yekushanda inoderedza kuwanda kwekushandiswa kwemidziyo, inoderedza kushandiswa kwezviwanikwa uye kuburitswa kwekabhoni. Kuverengerwa kweimwe kambani yekudzivirira nharaunda kunoratidza kuti kushandisa granite base kune imwe PCB drilling device kunogona kuderedza kuburitswa kwekabhoni nematani matatu muhupenyu hwayo hwese, izvo zvinoenderana nemafambiro ekuchinja kwegreen indasitiri yekugadzira.

Kubva pakudzora kwakarurama kwe micron-level kusvika pakugadzirisa mitengo yakazara, ma granite bases ari kuchinja mwero wemaitiro ekuboorera PCB nemabhenefiti awo asingatsiviwe ekushanda. Munguva ino yekudiwa kwakanyanya kwema 5G neAI chips, kusarudza granite base hakusi kungodyara mumhando yechigadzirwa chete asiwo danho rakakosha rekutora nzvimbo yepamusoro yetekinoroji.

Nguva yekutumira: Chikumi-17-2025