Mukugadzira zvinhu nemazvo uye metrology, granite slab ndiyo hwaro husingapokane—nzvimbo yekuyera zvinhu nehukuru hwayo. Kugona kwayo kubata denderedzwa rakakwana hakusi chinhu chemuzvarirwo chete, asi mhedzisiro yemaitiro ekuumba akarongwa zvakanaka, anoteverwa nekugadzirisa kwakarongeka. Asi rwendo rwupi rwekupedzisira rwunotorwa negranite slab kuti isvike pakukwana kwakadaro, uye ndeapi maitiro anodiwa kuti irambe iripo? Kune mainjiniya nevatungamiriri vemhando yepamusoro, kunzwisisa mavambo ekunyatsojeka uku uye matanho anodiwa ekuchengetedza kwakakosha pakuchengetedza mhando yekugadzira.

Chikamu 1: Maitiro Ekuumba—Kusatsetseka Kweinjiniya

Rwendo rwegranite slab, kubva pabhuroko rakachekwa-chekwa kusvika papuratifomu yepamusoro, runosanganisira matanho akatevedzana ekukuya, kugadzikana, uye kupedzisa, chimwe nechimwe chakagadzirirwa kuderedza zvishoma nezvishoma kukanganisa kwehukuru.

Pakutanga, mushure mekucheka, slab inoiswa muRough Shaping and Grinding. Danho iri rinobvisa zvinhu zvakawanda kuti pave ne geometry yekupedzisira uye rough flatness. Chinhu chakakosha ndechekuti, maitiro aya anoshandawo kuburitsa zvakawanda zvekushushikana kuripo kunoungana mudombo panguva yekuchera nekucheka kwekutanga. Nekubvumira slab kuti "igadzikane" uye igarezve mushure medanho rega rega rekubvisa zvinhu, tinodzivirira kudonha kwehukuru hwemangwana, tichivimbisa kugadzikana kwenguva refu.

Kuchinja kwechokwadi kunoitika panguva yeThe Art of Precision Lapping. Lapping inzira yekupedzisira, yakasarudzika zvikuru inonatsa nzvimbo yakati sandara kuita plane yekutarisa yakasimbiswa. Uku hakusi kukuya kwemuchina; ibasa rakangwarira, rinokurumidza kuderera, uye rine simba guru. Tinoshandisa makemikari akapfava, akasununguka—kazhinji dhaimani—akasungirirwa muchinhu chine mvura, akaiswa pakati pegranite pamusoro neplate yesimbi yakakandwa. Kufamba kwacho kunodzorwa nokungwarira kuti zvinhu zvibviswe zvakaenzana pamusoro. Mhedzisiro iyi yeavhareji, inodzokororwa nemaoko uye nehunyanzvi mumatanho anodzokororwa, zvishoma nezvishoma inonatsa kutsamira kusvika mukati mema microns kana kunyange ma sub-microns (kusangana nezvinodiwa zvakasimba seASME B89.3.7 kana ISO 8512). Kunyatsojeka kunowanikwa pano hakusi pamusoro pemuchina asi pamusoro pehunyanzvi hwemushandisi, hwatinoona sebasa rinokosha, risingatsiviwi.

Chikamu 2: Kugadzirisa—Kiyi Yekuti Zvinhu Zvirambe Zvakarurama

Purati yepamusoro pegranite chishandiso chinonyatsoshanda nemazvo, kwete bhenji rekushandira. Kana yangobvumidzwa, kugona kwayo kuchengetedza kururama kunoenderana chete nemitemo yemushandisi uye nharaunda.

Kudzora Zvakatipoteredza ndicho chinhu chikuru chinokanganisa kururama kwegranite. Kunyange zvazvo granite ine thermal expansion yakaderera (COE), musiyano wekupisa pakati pepamusoro nepazasi (vertical temperature gradient) unogona kukonzera kuti slab yese iite dome kana kukotama zvishoma. Saka, plate yacho inofanira kuchengetedzwa kure nezuva rakananga, mhepo inotonhodza, uye kupisa kwakanyanya. Nzvimbo yakanaka inochengetedza 68°F ± 1°F (20℃ ± 0.5℃).

NezveMashandisirwo neKuchenesa Protocol, kushandiswa kwenzvimbo nguva dzose kunokonzera kusakara kusina kuenzana. Kuti tirwise izvi, tinokurudzira kuti nguva nenguva uchitenderedza slab iri pachigadziko chayo uye uchigovera mabasa ekuyera pamusoro pese. Kuchenesa nguva dzose kunosungirwa. Guruva nemarara akapfava zvinoshanda sezvinhu zvinobvisa kukara, zvichikurumidzisa kupera. Zvishandiso zvekuchenesa granite chete, kana kuti isopropyl alcohol yakachena, ndizvo zvinofanira kushandiswa. Usamboshandisa sipo dzemumba kana zvishandiso zvekuchenesa zvinobva mumvura zvinogona kusiya zvasara zvinonamira kana, kana paine mvura, kutonhora kwenguva pfupi uye kukanganisa pamusoro. Kana plate yacho isingashande, inofanira kuvharwa nechifukidziro chakachena, chakapfava, chisingakuvadzi.

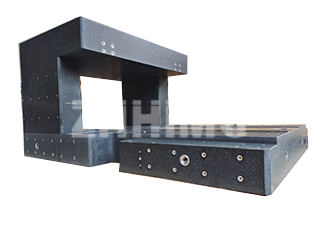

Chekupedzisira, nezveKugadzirisazve uye Kuvandudza, kunyangwe nekungwarira kwakakwana, kupfeka hakudzivisiki. Zvichienderana negiredhi rekushandisa (semuenzaniso, Giredhi AA, A, kana B) nebasa rekushandisa, plate yegranite inofanira kugadziriswa zviri pamutemo mwedzi yega yega 6 kusvika 36. Nyanzvi yehunyanzvi inoshandisa zvishandiso zvakaita se autocollimators kana laser interferometers kuti iongorore kutsauka kwenzvimbo. Kana plate ikadarika giredhi rayo rekutsungirira, ZHHIMG inopa masevhisi ehunyanzvi ekugadzirisazve. Maitiro aya anosanganisira kudzosa lap chaiyo panzvimbo yedu kana kufekitori yedu kuti tigadzirise kugadzikana kwepakutanga kwakabvumidzwa, nekugadzirisa hupenyu hwechishandiso.

Nekunzwisisa maitiro ekugadzira zvinhu zvakakosha uye kuzvipira kurongeka kwakasimba kwekugadzirisa, vashandisi vanogona kuve nechokwadi chekuti mapuratifomu avo egranite anoramba ari hwaro hwakavimbika hwezvinodiwa zvavo zvese zvemhando yepamusoro, makumi emakore mushure memakore.

Nguva yekutumira: Gumiguru-24-2025