Muminda yakaita semiconductor kugadzira uye kunyatsoyeresa zviridzwa, iko kurongeka kwemapuratifomu egranite kunoratidza zvakananga kushanda kwemhando yemidziyo. Kuona kuti kurongeka kwepuratifomu kunoenderana nezviyero, kuedza kunofanirwa kuitwa kubva pamativi maviri: kutariswa kwezviratidzo zvakakosha uye kutevedzera zvakajairwa. .

Core chiratidzo chekuona: Multi-dimensional kudzora kwechokwadi

Kuonekwa kweflatness: Kusarudza "kupfava" kwendege yereferensi

Flatness ndiyo inonyanya kuratidza mapuratifomu egranite, uye inowanzoyerwa nelaser interferometers kana mazinga emagetsi. Iyo laser interferometer inokwanisa kunyatso kuyera maminiti ekusuduruka papuratifomu nekubudisa danda relaser uye kushandisa musimboti wekukanganisa kwechiedza, nekunyatso kusvika padanho repasi-micron. Chiyero chemagetsi chinoyera nekufamba kakawanda uye chinodhirowa matatu-dimensional contour mepu yepapuratifomu kuti ione kana paine maprotrusions emunharaunda kana depression. Semuenzaniso, mapuratifomu egranite anoshandiswa mumichina ye semiconductor photolithography anodiwa kuti ave neflatness ye ± 0.5μm/m, zvichireva kuti mutsauko wehurefu mukati mehurefu hwemamita 1 haufanirwe kudarika hafu yemakromita. Chete kuburikidza nemhando yepamusoro-chaiyo yekuona michina inogona chiyero chakasimba ichi kuvimbiswa. .

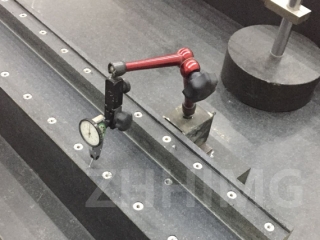

2. Kuonekwa kwakatwasuka: Ita shuwa "kutwasuka" kwemutsara wekufamba

Kune mapuratifomu anotakura zvinhu zvinofamba zvakanaka, kutwasanuka kwakakosha. Nzira dzakajairika dzekuonekwa inzira yewaya kana laser collimator. Iyo nzira yewaya inosanganisira kumisa yakakwirira-chaiyo waya dzesimbi uye kuenzanisa mukaha pakati pepuratifomu uye waya dzesimbi kuti uone kutwasuka. Iyo laser collimator inoshandisa mutsara wekuparadzira maitiro e laser kuona mutsara kukanganisa kweiyo yekumisikidza pamusoro pepuratifomu gwara renjanji. Kana iyo yakatwasuka ikasasangana neyakajairwa, ichaita kuti michina ifambe panguva yekufamba, ichikanganisa kugadzirisa kana kuyerwa kwechiyero. .

3. Kuonekwa kwehukukutu hwepamusoro: Iva nechokwadi che "kunaka" kwekusangana

Kushata kwepamusoro kwepuratifomu kunokanganisa kukodzera kwekuiswa kwechikamu. Kazhinji, stylus roughness mita kana optical microscope inoshandiswa pakuona. Chiridzwa chemhando yestylus chinorekodha shanduko yehurefu hweiyo microscopic mbiri nekubata papuratifomu nepepuru yakanaka. Optical microscopes inogona kuona zvakananga kutaridzika kwepamusoro. Mukushandiswa kwepamusoro-soro, kushata kwepamusoro kwemapuratifomu egranite kunoda kudzorwa paRa≤0.05μm, iyo yakaenzana negirazi-yakafanana nemhedzisiro, kuve nechokwadi chekuti zvikamu zvakanyatsokwana zvinokwana zvakasimba panguva yekuisa uye kudzivirira kuzunguzika kana kusimuka kunokonzerwa nemagapu. .

Iwo chaiwo mwero anotevera: mirairo yenyika uye kutonga kwemukati kwebhizinesi

Parizvino, pasi rose, ISO 25178 uye GB/T 24632 zviyero zvinowanzo shandiswa sehwaro hwekuona kurongeka kwemapuratifomu egranite, uye kune kupatsanurwa kwakajeka kwezviratidzo senge flatness uye kutwasuka. Pamusoro pezvo, mabhizinesi ekugadzira epamusoro-soro anowanzo kuseta zvakanyanya kuomarara mukati mekutonga zviyero. Semuyenzaniso, iyo inodiwa flatness yegranite papuratifomu yemuchina wephotolithography ndeye 30% yakakwira kupfuura mwero wepasi rose. Paunenge uchiitisa bvunzo, iyo yakayerwa data inofanirwa kuenzaniswa neinoenderana zviyero. Mapuratifomu chete anotevedzera zvizere zviyero anogona kuve nechokwadi chekuita kwakagadzikana mumidziyo chaiyo. .

Kuongorora huchokwadi hwemapuratifomu egranite ipurojekiti yakarongeka. Chete nekunyatso kuyedza zviratidzo zvepakati senge flatness, kutwasanuka, uye kushata kwepasi, uye kuomerera kune dzepasirese uye bhizinesi zviyero, ndipo panogona kuvimbiswa kurongeka kwepamusoro uye kuvimbika kwepuratifomu, kuisa hwaro hwakasimba hwenzvimbo dzekugadzira dzepamusoro-soro semiconductors uye zviridzwa zvakaringana.

Nguva yekutumira: May-21-2025