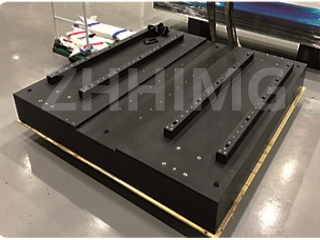

Nzira dzemagranite matema zvinhu zvakakosha mumichina yakawanda yekunyora nemazvo, senge michina yeCNC, michina yekuyera macoordinate, uye michina yekuyera yemaziso. Dzinofarirwa nekuda kwekugadzikana kwadzo kwakanaka, kuramba kupfeka zvakanyanya, uye kushaya simba kwekuwedzera kwekupisa. Zvisinei, kungofanana nechero chinhu, dzinogona kukuvara nekuda kwekusakara, kusabatwa zvakanaka, kana zvinhu zvakatipoteredza. Muchinyorwa chino, tichakurukura maitiro ekugadzirisa chitarisiko chenzira dzemagranite matema dzakakuvara uye kugadzirisazve kururama kwadzo.

Kugadzirisa Chitarisiko:

Kuonekwa kwenzira dzegranite nhema kunogona kukuvara nenzira dzakasiyana-siyana, kusanganisira kukwenya, mavara, ngura, uye machipisi. Heano mamwe matanho ekugadzirisa.

1. Chenesa nzvimbo yacho - Usati watanga kugadzirisa, zvakakosha kuchenesa nzvimbo yacho zvakanaka kubvisa tsvina, mafuta, kana marara. Shandisa jira rakapfava, rakanyorova uye sipo yakapfava kuti uchenese nzvimbo yacho zvinyoronyoro. Dzivisa kushandisa michina inokwenya kana zvishandiso zvinogona kukwenya nzvimbo yacho.

2. Bvisa mavara - Kana paine mavara akaomarara pamusoro, unogona kushandisa granite stain remover yakakosha inowanikwa pamusika. Isa pamavara acho worega agare kwemaminitsi mashoma. Wobva wapukuta nejira rakachena wosuka pamusoro nemvura.

3. Poresha pamusoro - Kuti udzorere kupenya uye kupenya kwegwara regranite dema, unogona kushandisa granite polishing compound yakakosha. Isa poreshi shoma pamusoro uye shandisa jira rakapfava, rakaoma kuti rifukidze kusvika pamusoro papenya uye papenya.

4. Zadza machipisi - Kana paine machipisi kana makomba pamusoro, unogona kushandisa epoxy filler ine zvikamu zviviri kuti uzadze. Sanganisa zvikamu zviviri zve epoxy zvakanaka wozviisa pachipisi uchishandisa kamuchina kadiki. Rega zviome kwemaawa mashoma, wozozvichenesa kuti zvinyatsoyerera nepamusoro pazvo.

Kuenzanisa Kwakarurama:

Kururama kwenzira dzemagranite matema kunogona kukanganiswa nekuda kwezvikonzero zvakasiyana-siyana, zvinosanganisira kusakara, kuchinja kwetembiricha, uye kusabatwa zvakanaka. Heano mamwe matanho ekugadzirisazve kururama kwenzira dzemagranite.

1. Tarisa kuti yakatsetseka sei - Danho rekutanga rekugadzirisazve kururama kwegwara regranite dema nderekutarisa kuti yakatsetseka sei uchishandisa straightedge chaiyo kana granite surface plate. Kana paine nzvimbo dzakakwirira kana nzvimbo dzakaderera, unogona kushandisa hand scraper kana diamond lapping plate kuti ubvise.

2. Tarisa parallelism - Danho rinotevera nderekutarisa parallelism yegwara regranite dema maererano ne axis yemuchina. Unogona kushandisa precision level kana laser level kuti uite izvi. Kana paine chero kutsauka, unogona kugadzirisa leveling screws kana shims kuti udzoserwe kune tolerance yaunoda.

3. Tarisa kururama kwenzvimbo - Danho rekupedzisira nderekutarisa kururama kwenzvimbo yegwara regranite nhema uchishandisa chishandiso chekuyera zvakarurama, senge dial indicator kana laser interferometer. Kana paine musiyano, unogona kugadzirisa ma parameter emuchina, senge feed rate, cutting speed, kana acceleration, kuti uwedzere kururama.

Mhedziso:

Kugadzirisa chitarisiko uye kugadzirisa kururama kwemigwagwa yegranite nhema kunoda hunyanzvi hwepamusoro, hunyanzvi, uye kunyatsorongeka. Zvakakosha kutevedzera maitiro akakodzera uye kushandisa maturusi nemidziyo yakakodzera kuti uve nechokwadi chekuti basa rekugadzirisa raitwa nemazvo. Nekuita izvi, unogona kuwedzera hupenyu hwemigwagwa yegranite nhema uye kuve nechokwadi chekuti michina yako inoshanda zvakanaka.

Nguva yekutumira: Ndira-30-2024