Mumunda wepicosecond-level laser yekumaka michina, kunyatsoita ndiyo musimboti chiratidzo chekuongorora mashandiro emidziyo. Nheyo, semutakuri wakakosha weiyo laser system uye chaiyo zvikamu, zvinhu zvayo zvinokanganisa kugadzikana kwekugadzirisa kurongeka. Granite uye simbi yakakandwa, sezvinhu zviviri zvakajairwa zvigadziko, zvine misiyano yakakura mune chaiyo yekumisikidza maitiro panguva yepicosecond-level Ultra-fine processing. Ichi chinyorwa chinozoongorora zvakadzama mabhenefiti ekuita uye zvakaipira zvevaviri kupa hwaro hwesainzi hwekusimudzira michina. .

Material properties inosarudza hwaro hwemazvo

Granite idombo rinopisa rinoumbwa kuburikidza nemaitiro e geological pamusoro pemazana emamiriyoni emakore. Chimiro chayo chekristaro chemukati chakaoma uye yunifomu, ine mutsara wekuwedzera coefficient yakaderera se 0.5-8 × 10⁻⁶/℃, inofananidzwa neiyo chaiyo alloys senge indium simbi. Hunhu uhu hunoita kuti shanduko yedimensional iite kunge isingaite kana tembiricha yakadzika ikachinja, zvinobudirira kudzivirira nzira yekubvisa uye kukanganisa kwemuchina kunokonzerwa nekuwedzera kwekupisa uye kuderera. Pamusoro pezvo, density yegranite yakakwira kusvika 2.6-2.8g/cm³, iyo ine musikirwo ine yakanakisa vibration yekunyudza. Iyo inogona kukurumidza kudzora iyo yakakwira-frequency vibrations inogadzirwa panguva yekugadziriswa kwelaser, kuve nechokwadi kugadzikana kweiyo optical system uye zvikamu zvinofamba. .

Cast iron bases inoshandiswa zvakanyanya nekuda kwekuita kwavo kwakanaka kwekukanda uye mutengo wakanakira. Iyo yakajairwa flake graphite chimiro chegrey cast iron inoiisa pamwe nekunyorovesa kuita, iyo inogona kutora anenge 30% kusvika 50% yesimba rekuzunguza. Zvisinei, iyo coefficient yekuwedzera kwekushisa kwesimbi yakakandwa inenge 10-12 × 10⁻⁶/℃, iyo 2-3 nguva yegranite. Pasi pekuunganidza kwekupisa kunokonzerwa nekugara kwenguva refu kuenderera mberi, dimensional deformation inowanzoitika. Zvichakadaro, pane kukanda kunetseka mukati mesimbi yakakandwa. Sezvo kushushikana kunoburitswa panguva yekushandiswa kwemaitiro, zvinogona kukonzera shanduko isingachinjike mukupfava uye perpendicularity yechigadziko. .

Iyo chaiyo attenuation mechanism mune picosecond-level kugadzirisa

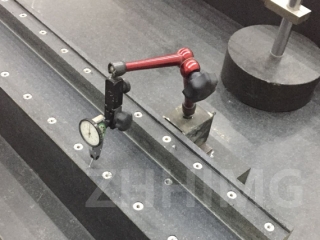

Picosecond laser processing, ine ultra-short pulse maitiro, inogona kuwana yakanaka kugadzirisa pa sub-micron level kana kunyange nanometer level, asi zvakare inoisa zvakaomesesa zvinodiwa pakugadzikana kwemidziyo. Iyo granite base, ine yakagadzikana yemukati chimiro, inogona kudzora iyo vibration mhinduro paiyo sub-micron nhanho pasi peyakanyanya-frequency laser impact, inonyatso kuchengetedza kurongeka kweiyo yekutarisa kwelaser. Iyo yakayerwa data inoratidza kuti laser yekumaka muchina ine base yegranite ichiri kuchengetedza mutsara wakafara kutsauka mukati me ± 0.5μm mushure mekuenderera kwe8-awa piccosecond processing. .

Kana iyo yakakandwa chigadziko chesimbi chinoratidzwa kune yakakwira-frequency vibration yepicosecond laser, chimiro chemukati chezviyo chinozosangana nekuneta kwe microscopic nekuda kwekuenderera mberi kwekuita, zvichikonzera kudzikira kwekusimba kwechigadziko. Kuongorora dhata kubva kune imwe semiconductor yekugadzira bhizinesi inoratidza kuti mushure memwedzi mitanhatu yekushanda, iko kurongeka kwekugadzirisa chiyero chemidziyo ine mabhesi esimbi yakakandwa inosvika 12%, inonyanya kuratidzwa sekuwedzera kwekushata kwemitsara mitsetse uye kuwedzera kwekukanganisa kwekumisikidza. Zvichakadaro, simbi yakakandwa ine hunyoro hunyoro hwezvakatipoteredza. Kushandiswa kwenguva refu kunowanzoita ngura, zvichiwedzera kukurumidza kuparara kwechokwadi. .

Kuongororwa kwekusiyana kwekuita mumashandisirwo anoshanda

Mundima ye 3C yemagetsi chaiyo chikamu chekugadzirisa, bhizinesi rinozivikanwa rakaita bvunzo yekufananidza pakuita kwemidziyo yemhando mbiri dzezvigadziko. Mukuyedza, maviri epicosecond laser yekumaka machina ane dhizaini yakafanana aive akashongedzerwa negranite uye akakandwa mabhesi esimbi ekucheka uye kumaka girazi renhare mbozha skrini nehupamhi hwe0.1mm. Mushure memaawa mazana maviri ekuenderera mberi kwekugadzirisa, mwero wekuchengetedza wekugadziriswa kweiyo granite base midziyo yaive 98.7%, nepo iyo yekukanda simbi base midziyo yaingova 86.3%. Micheto yegirazi yakagadziriswa neiyo yekupedzisira yairatidza pachena kusakwana kwesawtooth. .

Mukugadzira zvinhu zvemuchadenga, iyo data yenguva refu yekuongorora yeimwe tsvakurudzo intuitively inoratidza misiyano: The laser marking machine ine granite base ine cumulative precision attenuation isingasviki 3μm mukati memakore mashanu ehupenyu hwebasa; Nekudaro, mushure memakore matatu, iko kukanganisa kwekugadziriswa kwesimbi yakakandwa base midziyo yakakonzerwa nekugadziriswa kwegadziko yakapfuura chiyero che ± 10μm, uye iyo yakazara muchina kurongeka kunofanirwa kuitwa. .

Mazano ekuvandudza sarudzo

Kana mabhizinesi atora yakakwirira-chaiyo uye yakareba-kutenderera yakagadzikana kugadzirisa sekuda kwavo kwepakati, kunyanya muminda yakaita semiconductor machipisi uye chaiyo optical zvikamu, zvigadziko zvegranite, nekudzikama kwadzo kwemafuta uye kuramba kwekudedera, isarudzo yakanaka yekusimudzira. Kunyangwe mutengo wayo wekutanga wekutenga uri 30% kusvika 50% yakakwira kupfuura iyo yesimbi yakakandwa, kubva pamaonero ehupenyu hwakazara mutengo, iyo yakaderedzwa frequency yechaiyo calibration uye kuderera kwemidziyo yekugadzirisa kunogona kuwedzera zvakanyanya mabhenefiti. Kune mamiriro ekushandisa ane yakaderera kurongeka kwezvinodikanwa uye mabhajeti mashoma, mabhesi esimbi akakanda anogona achiri kushandiswa semhinduro yekuchinja pasi pemamiriro ekudzora zvine musoro nharaunda yekushandisa. .

Nekunyatso kuenzanisa iyo chaiyo attenuation maitiro egranite uye simbi yakakandwa mupiccosecond-level processing, zvinogona kuoneka kuti kusarudza iyo yakakodzera base zvinhu inhanho yakakosha yekuvandudza iko kurongeka uye kuvimbika kweiyo laser yekumaka muchina. Mabhizinesi anofanirwa, maererano nezvinodiwa zvetekinoroji uye kufunga kwemitengo, kuita sarudzo dzesainzi pane hwaro hwekusimudzira chirongwa chekupa hwaro hwemidziyo yakasimba yekugadzira-yekupedzisira. .

Nguva yekutumira: May-22-2025