Mumamiriro ekugadzira zvinhu ari kuchinja nekukurumidza, kunyatsorongeka kuchiri muganhu wekupedzisira. Nhasi, hunyanzvi hutsva hwakagadzirirwa kutsanangura patsva mwero weindasitiri: Precision Marble Three-Axis Gantry Platform, chishamiso cheinjiniya chinosanganisa kugadzikana kwegranite yechisikigo nedhizaini yemichina yemazuva ano kuti uwane kururama kwe micron-level kwaimbofungidzirwa kuti hakugone kuwanikwa mumaindasitiri.

Sainzi Iri Kutsigira Kugadzikana

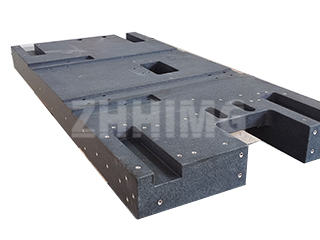

Pakati pechinhu ichi chehunyanzvi pane sarudzo yezvinhu zvisingatarisirwi: granite yechisikigo. Hwaro hwemarble hwakagadzirwa nepuratifomu iyi hwe1565 x 1420 x 740 mm hausi kungori runako rwekugadzira chete—imhinduro yesainzi kune dambudziko rekare rekuchengetedza kugadzikana mumasisitimu akanyatsogadzirwa. "Kuwedzera kwekupisa kweGranite kwakaderera zvakanyanya (2.5 x 10^-6 /°C) uye hunhu hwakasiyana hwekunyorovesa zvinopa hwaro hunodzivirira kushanduka-shanduka kwekushisa kwezvakatipoteredza uye kudedera kwemuchina zviri nani kupfuura zvivakwa zvesimbi zvechinyakare," anotsanangura Dr. Emily Chen, injiniya mukuru wemuchina paPrecision Engineering Research Institute.

Iyi mukana wechisikigo inoshandura zvakananga kune zviyero zvekushanda zviri kuchinja misoro mumaindasitiri. Puratifomu iyi inowana mukana wekudzokorora ±0.8 μm—zvichireva kuti inogona kudzokera kune chero nzvimbo ine kutsauka kudiki pane wavelength yechiedza chinoonekwa—uye ±1.2 μm kunyatsorongeka kwekuisa mushure mekubhadharwa, zvichiisa mwero mutsva wemasisitimu ekudzora kufamba.

Hunyanzvi hweUinjiniya muMotion

Kupfuura hwaro hwayo hwakagadzikana, dhizaini ye three-axis gantry yepuratifomu iyi ine zvinhu zvitsva zvakasiyana-siyana. X-axis ine sisitimu yekufambisa mbiri inobvisa torsional deformation panguva yekufamba nekukurumidza, nepo ese ari maviri X neY axes achipa kufamba kwakanaka kwe750 mm ne ≤8 μm straightness mumatanho ese ari maviri akatwasuka uye akatwasuka. Iyi nhanho ye geometric usahihi inoita kuti kunyangwe 3D trajectories dzakaomarara dzinochengetedza sub-micron accuracy.

Kugona kwekufamba kwesystem iyi kunoratidza kuenzana kukuru pakati pekumhanya nekunyatsorongeka. Kunyange hazvo kumhanya kwayo kwepamusoro kwe1 mm/s kungaita sekunge kuri kushoma, yakagadzirirwa maapplication anoda kudzora zvakanaka uye kuskena zvishoma nezvishoma—apo kurongeka kunokosha kupfuura kufamba nekukurumidza. Kusiyana neizvi, kugona kwekumhanyisa 2 G kunoita kuti ikwanise kutanga nekumira, zvakakosha kuti irambe ichishanda zvakanaka mukuongorora kwakarurama.

Iine mutoro unorema 40 kg uye 100 nm resolution (0.0001 mm), puratifomu iyi inobatanidza musiyano uripo pakati pekushandiswa kwezvigadzirwa zvishoma uye kusimba kwemaindasitiri—kusiyana-siyana kuri kukonzera kufarira kukuru muzvikamu zvekugadzira.

Kuchinja Maindasitiri Akakosha

Zvinorehwa nekubudirira uku kwakarurama zvinopararira muzvikamu zvakawanda zvetekinoroji yepamusoro:

Mukugadzira ma semiconductor, uko kunyangwe zvikanganiso zve nanometer-scale zvinogona kuita kuti machipisi asashande, kugadzikana kwepuratifomu kuri kuchinja maitiro ekuongorora ma wafer uye photolithography alignment. "Tiri kuona huwandu hwekuona zvikanganiso huri kuwedzera ne37% mukuyedza kwekutanga," anodaro Michael Torres, mukuru wemainjiniya wekugadzira michina ye semiconductor. "Kudzivirira kwe vibration base ye marble kwakabvisa micro-wobble yaimbovhara maficha e sub-50 nm."

Kugadzira magirazi ekuona zvakanaka ndeimwe nzira inobatsira. Maitiro ekupukuta magirazi nekubatanidza magirazi ayo aimboda maawa ekugadzirisa nemaoko nekukurumidza zvino anogona kuitwa otomatiki nekuisa magirazi epasi pema micron, zvichideredza nguva yekugadzira ukuwo zvichivandudza kushanda kwemaziso.

Mukutsvaga kwezvekurapa, puratifomu iyi iri kugonesa budiriro mukushandiswa kwemasero ega uye mifananidzo ye microscopic ine resolution yepamusoro. Dr. Sarah Johnson weStanford's Biomedical Engineering Department anoti, "Kugadzikana uku kunotibvumira kuramba tichitarisa pazvimiro zvemasero kwenguva yakareba, tichitora mifananidzo inofamba-famba inoratidza maitiro ehupenyu akambovanzwa nekudonha kwemidziyo."

Zvimwe zvinoshandiswa zvikuru zvinosanganisira michina yekuyera ine macoordinate akanyatsogadzirwa (CMMs), microelectronics packaging, uye zvishandiso zvesainzi zvepamusoro-soro—nzvimbo dzese uko musanganiswa wepuratifomu uyu wekururama, kugadzikana, uye mutoro unobata zvipingamupinyi zvehunyanzvi zvenguva refu.

Remangwana reKugadzira Zvinhu Zvakanyatsogadzirwa

Sezvo kugadzira zvinhu kuchiri kuramba kuchienderera mberi nekuedza kwayo kudiki uye kushanda zvakanaka, kudiwa kwemasisitimu ekumisa zvinhu nemazvo kuchawedzera. Precision Marble Three-Axis Gantry Platform haingomiriri chete kuvandudzwa kushoma asi shanduko huru mukuti kunyatsoita zvinhu nemazvo kunowanikwa sei—kushandisa zvinhu zvechisikigo pamwe chete neinjiniya yepamusoro pane kungovimba chete nemasisitimu akaomarara anoshanda.

Kune vagadziri vari kutarisana nematambudziko eIndustry 4.0, puratifomu iyi inopa mukana wekuona remangwana reinjiniya yekunyora nemazvo. Inguva yemberi apo muganhu uri pakati pe "kuramba uchinyatsoongorora" ne "kugadzirwa kwemaindasitiri" unoramba uchidzikira, zvichigonesa hunyanzvi huchaumba zvese kubva kumagetsi echizvarwa chinotevera kusvika kumidziyo yekurapa inoponesa hupenyu.

Sezvakataurwa nemumwe muongorori weindasitiri: "Munyika yekugadzira zvinhu nemazvo, kugadzikana hakusi chinhu chinongoitika chete—ndiyo hwaro hwakavakirwa zvimwe zvinhu zvese zvinofambira mberi. Iyi puratifomu haingosimudziri chete; inoivakazve zvizere."

Nguva yekutumira: Gumiguru-31-2025