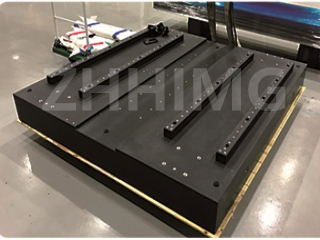

Muindasitiri ye semiconductor, kuongorora wafer inzira huru yekuona kuti chip yacho yakanaka uye inoshanda zvakanaka, uye kururama nekugadzikana kwetafura yekuongorora kunoita basa guru mumhedzisiro yekuona. Granite base ine hunhu hwayo hwakasiyana, inova sarudzo yakakodzera yetafura yekuongorora wafer ye semiconductor, zvinotevera kubva muongororo yezvikamu zvakawanda kwauri.

Chekutanga, chiyero chevimbiso chaiyo

1. Kutwasuka uye kutwasuka kwakanyanya: Hwaro hwegranite hunogadziriswa netekinoroji yepamusoro yekugadzirisa, uye kutwasuka kunogona kusvika ±0.001mm/m kana kutonyanya kutwasuka, uye kutwasuka kwakanakawo. Mukuita kwekuongorora wafer, denderedzwa repamusoro rinopa rutsigiro rwakasimba rwewafer uye rinoona kuti probe yemidziyo yekuongorora uye majoini e solder ari pamusoro pewafer anobatana zvakanaka.

2. Kuwanda kwemafuta kwakaderera zvikuru: kugadzirwa kwe semiconductor kunonzwa shanduko dzetembiricha, uye kuwanda kwemafuta kwakaderera zvakanyanya, kazhinji kacho kunenge 5×10⁻⁶/℃. Kana puratifomu yekuona iri kushanda, kunyangwe tembiricha yemhepo ichichinja-chinja, saizi yegranite base inochinja zvishoma. Semuenzaniso, muworkshop yekupisa kwakanyanya muzhizha, tembiricha yepuratifomu yekuona simbi yakajairika inogona kukonzera kuti nzvimbo yewafer nemidziyo yekuona ichinje, zvichikanganisa kururama kwekuona; Puratifomu yekuona matombo egranite inogona kuchengetedza kugadzikana, kuve nechokwadi chekuti nzvimbo yewafer nemidziyo yekuona iri kurongeka panguva yekuona, uye kupa nharaunda yakagadzikana yekuona zvakanyatsonaka.

Chechipiri, divi rekugadzikana

1. Chimiro chakagadzikana uye kuramba kuzununguka: Granite mushure memamiriyoni emakore ekuita kwe geological, chimiro chemukati chakasimba uye chakafanana. Munzvimbo yakaoma yefekitori ye semiconductor, kuzununguka kunokonzerwa nekushanda kwemidziyo yekunze nevashandi vanofamba-famba kunoderedzwa ne granite base.

2. Kurongeka kwekushandiswa kwenguva refu: kana tichienzanisa nezvimwe zvinhu, granite ine kuoma kwakanyanya, kuramba kupfeka kwakasimba, uye kuomarara kweMohs kunogona kusvika 6-7. Nzvimbo yegranite haipfeki nyore panguva yekurodha, kuburitsa zvinhu uye kuongorora wafer kakawanda. Zvichienderana nekushandiswa chaiko kwedata statistics, kushandiswa kwetafura yekuedza granite base, kushanda nguva dzose mushure memaawa 5000, kutwasuka uye kutwasuka kwakarurama kunogona kuramba kuripo kupfuura 98% yekururama kwekutanga, zvichideredza michina nekuda kwekupfekwa kwenheyo kunokonzerwa nenguva dzekugadzirisa nguva dzose, kuderedza mari yekushanda kwebhizinesi, kuve nechokwadi chekuti basa rekuyedza rinogara kwenguva refu.

Chechitatu, chiyero chakachena uye chinodzivirira kupindira

1. Kugadzirwa kweguruva shoma: nzvimbo yekugadzira semiconductor inofanirwa kuchena zvakanyanya, uye granite pachayo yakagadzikana uye haisi nyore kugadzira zvidimbu zveguruva. Munguva yekushanda kwepuratifomu yekuyedza, guruva rinogadzirwa nebase rinodzivirirwa kusvibisa wafer, uye njodzi ye short circuit uye open circuit inokonzerwa nezvidimbu zveguruva inoderedzwa. Munzvimbo yekutarisa wafer yeworkshop isina guruva, huwandu hweguruva hwakatenderedza tafura yekuongorora granite base hunogara huchidzorwa kusvika padanho rakaderera, zvichisangana nezvinodiwa zvekuchena kweindasitiri ye semiconductor.

2. Hapana kupindirana kwemagineti: michina yekuona inonzwa nharaunda yemagetsi, uye granite chinhu chisiri chemagnetic, chisingazokanganisa chiratidzo chemagetsi chemuchina wekuona. Mukushandisa tekinoroji yekuona maerekitironi nedzimwe nzira dzekuongorora dzinoda nharaunda yemagetsi yakanyanya, granite base inovimbisa kutumirwa kwakasimba kwechiratidzo chemagetsi chemuchina wekuona uye inovimbisa kururama kwemhedzisiro yebvunzo. Semuenzaniso, kana wafer ikaedzwa kushanda kwemagetsi kwakanyatsojeka, granite base inodzivirira kupindirana nezviratidzo zvemagetsi nemagetsi, kuitira kuti data rekuona riratidze hunhu hwemagetsi ewafer.

Nguva yekutumira: Kurume-31-2025