Munyaya yekugadzira nemazvo, pfungwa isiriyo inowanzotaurwa ndeyekuti "kurema kwakanyanya = kuomarara kwakasimba = kunyatsojeka kwakanyanya". Hwaro hwegranite, hune huwandu hwe2.6-2.8g/cm³ (7.86g/cm³ yesimbi yakakandwa), hwakawana kunyatsojeka kupfuura kwema micrometer kana kunyange nanometers. Seri kwechiitiko ichi "chinopikisana nepfungwa" kune kubatana kwakadzama kwe mineralogy, mechanics uye processing techniques. Izvi zvinotevera zvinoongorora misimboti yayo yesainzi kubva muzvikamu zvina zvikuru.

1. Kuwanda kwechinhu ≠ Kuomarara: Basa guru rekuvaka zvinhu

Chimiro chekristaro che "chisikigo cheuchi" chegranite

Granite inoumbwa nemakristaro emaminerari akadai sequartz (SiO₂) uye feldspar (KAlSi₃O₈), ayo akabatana zvakanyanya ne ionic/covalent bonds, zvichigadzira chimiro chakabatana chakafanana nehoneycomb. Chimiro ichi chinopa hunhu hwakasiyana:

Simba rekudzvanya rakafanana neresimbi yakakandwa: rinosvika 100-200 mpa (100-250 mpa yesimbi yakakandwa yegrey), asi elastic modulus yakaderera (70-100 gpa vs 160-200 gpa yesimbi yakakandwa), zvinoreva kuti kashoma kuti iite plastic deformation kana yashandiswa nesimba.

Kuburitswa kwechisikigo kwekushushikana kwemukati: Granite yakwegura kwemazana emamiriyoni emakore emaitiro e geological, uye kushushikana kwemukati kunosvika zero. Kana simbi yakakandwa yatonhodzwa (nekutonhora kwemhepo > 50℃/s), kushushikana kwemukati kunosvika 50-100 mpa kunogadzirwa, izvo zvinoda kubviswa ne annealing yekugadzira. Kana kurapwa kusina kunyatsojeka, kunogona kuchinjika kana ikashandiswa kwenguva refu.

2. Chimiro chesimbi "chine zvikanganiso zvakawanda" chesimbi yakakandwa

Simbi yakakandwa isimbi-kabhoni alloy, uye ine zvikanganiso zvakaita se flake graphite, pores uye shrinkage porosity mukati.

Matrix yekupatsanurwa kweGraphite: Graphite yakapwanyika yakaenzana ne "microcracks" yemukati, zvichikonzera kudzikira kwe30%-50% munzvimbo chaiyo yesimbi yakakandwa inotakura mutoro. Kunyangwe simba rekudzvanya riri rakakwirira, simba rekutenderera rakaderera (1/5-1/10 chete yesimba rekudzvanya), uye inogona kutsemuka nekuda kwekuwanda kwekumanikidzwa kwenzvimbo.

Kuwanda kwesimbi asi isina kuenzana: Simbi ine kabhoni kubva pa2% kusvika ku4%. Panguva yekukanda, kupatsanurwa kwezvinhu zvekabhoni kunogona kukonzera kuchinja kwehuwandu hwe ±3%, nepo granite iine kuenzana kwehuwandu hwezvicherwa kupfuura 95%, zvichiita kuti chimiro chigadzikane.

Chechipiri, mukana wekunyatsojeka wekudzikira kwehuwandu: kudzvinyirira kupisa nekudengenyeka kaviri

"Zvakanakira zvechisikigo" zvekudzora kushanduka kwekupisa

Kuwanda kwekuwedzera kwekupisa kunosiyana zvikuru: granite iri 0.6-5×10⁻⁶/℃, nepo simbi yakakandwa iri 10-12×10⁻⁶/℃. Tora hwaro hwemamita gumi semuenzaniso. Kana tembiricha ikachinja ne10℃:

Kuwedzera uye kudzikira kwegranite: 0.06-0.5mm

Kukura kwesimbi yakakandwa uye kupfupika: 1-1.2mm

Musiyano uyu unoita kuti granite ive "zero deformation" munzvimbo inodzorwa netembiricha chaiyo (senge ± 0.5℃ mu workshop ye semiconductor), nepo simbi yakakandwa ichida imwe thermal compensation system.

Musiyano wekupisa kwegranite: Kupisa kwegranite kuri 2-3W/(m · K), inova 1/20-1/30 chete yesimbi yakakandwa (50-80W/(m · K)). Muzviitiko zvekupisa zvemidziyo (sekunge tembiricha yemota inosvika 60℃), tembiricha yepamusoro yegranite iri pasi pe0.5℃/m, nepo yesimbi yakakandwa inogona kusvika 5-8℃/m, zvichikonzera kuwedzera kusina kuenzana kwenzvimbo uye kukanganisa kutwasuka kwegwara rekutungamira.

2. "Kuderedza simba kwechisikigo" kwekudzikisira kudedera

Nzira yekubvisa simba remuganhu wezviyo mukati: Kutsemuka kwezvikamu zvidiki uye kutsvedza kwemuganhu wezviyo pakati pemakristaro egranite zvinogona kubvisa simba rekudengenyeka nekukurumidza, nechiyero chekudzikisa che0.3-0.5 (kunyangwe simbi yakakandwa iri 0.05-0.1 chete). Kuedza uku kunoratidza kuti kana kudengenyeka kwe100Hz:

Zvinotora masekondi 0.1 kuti amplitude yegranite iore kusvika 10%

Simbi yakakandwa inotora masekondi 0.8

Musiyano uyu unogonesa granite kugadzikana ipapo ipapo mumichina inofamba inomhanya zvikuru (yakadai sekuskena musoro we coating 2m/s), kudzivirira kukanganisa kwe "vibration marks".

Mhedzisiro yekusasimba kwesimba: Kuwanda kwesimba kunoreva kuti huremu hudiki muhuwandu hwakafanana, uye simba resimba (F=ma) uye simba resimba (p=mv) rechikamu chinofamba zvakaderera. Semuenzaniso, kana furemu yegranite gantry yemita gumi (inorema matani gumi nemaviri) ikakurumidziswa kusvika ku1.5G zvichienzaniswa nefuremu yesimbi yakakandwa (matani makumi maviri), simba rekutyaira rinodzikiswa ne40%, simba rekutanga-kumira rinodzikira, uye kururama kwenzvimbo kunovandudzwa zvakanyanya.

III. Kubudirira mu "kunyatsoshanda" kwetekinoroji yekugadzirisa zvinhu

1. Kugona kuchinjika kune kugadzirisa kwakanyatsojeka

Kudzora "kukuya nekupukuta" kwe "crystal-level": Kunyangwe kuomarara kwegranite (6-7 paMohs scale) kwakakwira kupfuura kwesimbi yakakandwa (4-5 paMohs scale), chimiro chayo chemineral chakafanana uye chinogona kubviswa neatomu kuburikidza nedhaimani abrasive + magnetorheological polishing (kukora kwepolish imwe chete < 10nm), uye kuomarara kwepamusoro Ra kunogona kusvika 0.02μm (girazi). Zvisinei, nekuda kwekuvapo kwezvidimbu zvakapfava zvegraphite musimbi yakakandwa, "furplough effect" inowanzoitika panguva yekukuya, uye kuomarara kwepamusoro kwakaoma kuva pasi pane Ra 0.8μm.

Kubatsira kwe "low stress" kweCNC machining: Pakugadzirisa granite, simba rekucheka rinongori 1/3 yesimbi yakakandwa (nekuda kwekushomeka kwayo uye small elastic modulus), zvichibvumira kumhanya kwakanyanya kwekutenderera (100,000 revolutions paminiti) uye feed rates (5000mm/min), zvichideredza kupfeka kwemidziyo uye kuwedzera kushanda zvakanaka kwekugadzira. Imwe nyaya yemichina ye-five-axis inoratidza kuti nguva yekugadzirisa yegranite guide rail grooves ipfupi ne25% pane yesimbi yakakandwa, nepo kururama kuchivandudzwa kusvika ±2μm.

2. Musiyano mu "mhedzisiro inounganidzwa" yezvikanganiso zvemusangano

Maitiro echeni yehuremu hwakaderedzwa hwezvikamu: Zvikamu zvakaita semota nemaraidhi ekutungamira zvakabatana nemabhesi ane density yakaderera zvinogona kujekeswa panguva imwe chete. Semuenzaniso, kana simba remota yakatsetseka radzikiswa ne30%, kugadzirwa kwayo kwekupisa uye kudedera kunodererawo zvinoenderana, zvichigadzira kutenderera kwakanaka kwe "kunyatsojeka kwakavandudzwa - kushandiswa kwesimba kwakaderera".

Kugara kwenguva refu kwakarurama: Kuramba kwegranite ngura kwakapetwa ka15 kupfuura simbi yakakandwa (quartz inodzivirira kukurwa kweasidhi nealkali). Munzvimbo ine mhute ye semiconductor acid, kuchinja kwekuoma kwenzvimbo mushure memakore gumi ekushandiswa kushoma pane 0.02μm, nepo simbi yakakandwa ichida kukuyiwa nekugadziriswa gore rega rega, nekukanganisa kwakawanda kwe ±20μm.

Iv. Humbowo hweMaindasitiri: Muenzaniso Wakanakisisa weKuwanda Kwakaderera ≠ Kushanda Kwakaderera

Midziyo yekuyedza semiconductor

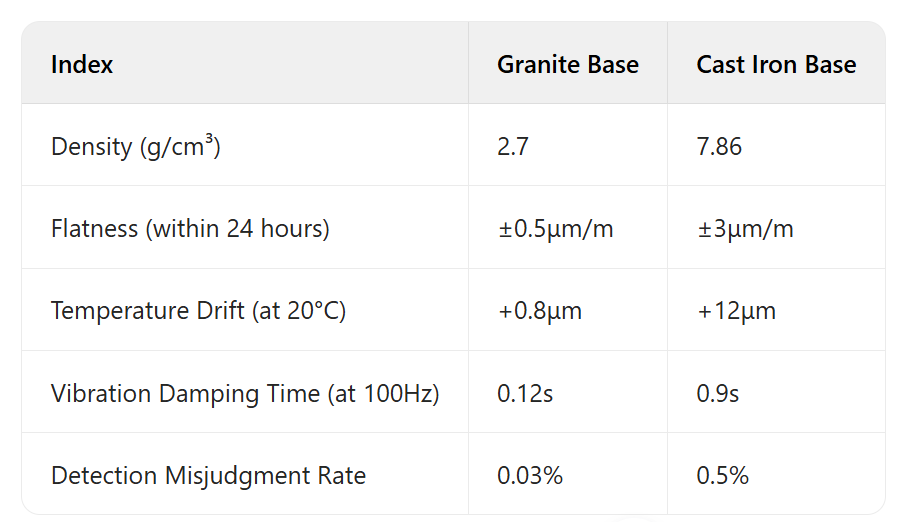

Ruzivo rwekuenzanisa rweimwe puratifomu yekuongorora wafer:

2. Zvishandiso zvemaziso zvakanyatsonaka

Chinoongorora magirazi cheNASA cheJames Webb Telescope chakagadzirwa negranite. Kunyatsoshandisa mukana wekuti simbi ine simba shoma (inodzikisa mutoro wesatellite) uye kuwedzera kwekupisa kwakaderera (yakagadzikana pakupisa kwakaderera kwe -270℃) ndiko kunoita kuti nano-level optical alignment ive nechokwadi, ukuwo njodzi yekuti simbi yakakandwa ive brittle pakupisa kwakaderera inobviswa.

Mhedziso: "Kugadzira pfungwa dzakasiyana-siyana" mune zvesainzi yezvinhu

Kubudirira kwakarurama kwematombo egranite kuri mukukunda kwezvinhu zve "structural uniformity > density, thermal shock stability > simple rigidity". Haisi kungori chete kuti density yayo yakaderera haina kusimba, asi yakawanawo kukwira kwakarurama kuburikidza nematanho akadai sekuderedza inertia, kugadzirisa thermal control, uye kugadzirisa ultra-precision processing. Chiitiko ichi chinoratidza mutemo mukuru wekugadzira nemazvo: zvinhu zvemazvo imhando yakakwana yeparameters ine mativi akawanda pane kuunganidzwa kuri nyore kwezviratidzo zvega. Nekuvandudzwa kwe nanotechnology uye kugadzira green, zvinhu zvegranite zvine density yakaderera uye high-performance zviri kutsanangura patsva maonero eindasitiri e "heavy" uye "light", "rigid" uye "flexible", zvichivhura nzira itsva dzekugadzira zvinhu zvepamusoro.

Nguva yekutumira: Chivabvu-19-2025