.

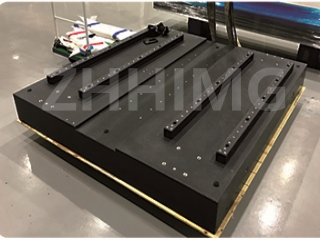

Kuongororwa kweaero injini blades kune zvakanyanyisa zvinodikanwa zvekugadzikana, kurongeka uye kuvimbika kwepuratifomu. Kuenzaniswa nemapuratifomu ekuongorora echinyakare akadai sesimbi yakakandwa uye aruminiyamu alloy, mapuratifomu egranite anoratidza zvakanakira zvisingadzoreki mune akawanda makiyi zviratidzo. .

I. Thermal Stability: A "Natural Shield" Kurwisana neTemperature Kupindira

Iyo coefficient yekuwedzera kwekupisa kwesimbi yakakandwa mapuratifomu inenge 10-12 × 10⁻⁶/℃, uye iyo yealuminium alloys yakakwirira se23 × 10⁻⁶/℃. Pasi pekupisa kunoitwa nekushanda kwemidziyo yekuona kana kushanduka kwekushisa kwezvakatipoteredza, dimensional deformation inowanzoitika, zvichikonzera kukanganisa kwekuona. Iyo coefficient yekuwedzera kwekushisa kwepuratifomu yegranite chete (4-8) × 10⁻⁶/℃. Mukati mekusiyana kwetembiricha ye ± 5 ℃, shanduko yedimensional ye1-mita-yakareba granite papuratifomu isingasviki 0.04μm, iyo ingangoita kufuratirwa. Iyi yekupedzisira-yakaderera kupisa kwekuwedzera hunhu inopa yakagadzikana yekunongedza pamusoro peiyo chaiyo midziyo yakadai se laser interferometers uye matatu-anoronga ekuyeresa michina, kudzivirira kuyerwa kutsauka kweblade contours kunokonzerwa nekupisa kwekupisa. .

Ii. Anti-vibration Performance: Iyo "Inoshanda Barriers" yekubvisa Vibration Interference

Mumusangano wekugadzira ndege, kuzunguzika kwezvakatipoteredza kunokonzerwa nekushanda kwematurusi emuchina uye kufamba kwevashandi kunowanzoitika. Aluminium alloy mapuratifomu ane kusasimba kwakakwana, uye mapuratifomu esimbi anokandwa ane mashoma ekunyorovesa kuita, zvichiita kuti zviome kunyatso buffer vibrations. Iyo dense crystal chimiro mukati mepuratifomu yegranite inoiisa iyo yakanakisa yekunyorovesa maitiro, ine daping ratio ye0.05-0.1, inova kashanu iyo yesimbi yakakandwa uye kagumi iyo yearuminiyamu alloy. Kana kudengenyeka kwekunze kuchiendeswa papuratifomu, inogona kudzikisira simba rekuzunguza neinopfuura 90% mukati memasekonzi 0.3, kuve nechokwadi chekuti michina yekuona inogona kuramba ichiburitsa data chaiyo munzvimbo inodedera. .

Iii. Kuomarara uye Kupfeka Kupokana: Iyo "Simba Yakasimba" Kuve nechokwadi chenguva refu Kurongeka.

Mushure mekushandiswa kwenguva yakati, chikuva chesimbi chakakandwa chinowanzoita kuneta kutsemuka, izvo zvinokanganisa kurongeka kwayo. Aluminium alloy mapuratifomu ane kuomarara kwakaderera uye kushomeka kusamira, zvichiita kuti zviome kushingirira kushandiswa nguva dzose kweanorema-basa rekuongorora michina. Kuwanda kwepuratifomu yegranite kunosvika 2.6-2.8g /cm³, simba rayo rekumanikidza rinopfuura 200MPa, uye kuoma kwayo kweMohs i6-7. Kana yaiswa pasi pemitoro inorema uye kukweshana kwenguva refu kubva kune blade yekuongorora michina, haina kujaira kupfeka kana deformation. Dhata kubva kune rimwe bhizinesi rendege rinoratidza kuti mushure mekugara uchishandiswa kwemakore masere, shanduko yekudzikama kwepuratifomu yegranite ichiri kudzora mukati me ± 0.1μm/m, nepo chikuva chesimbi chinoda kudzokororwa mushure memakore matatu chete. .

Iv. Kemikari Kugadzikana: Iyo "Yakagadzikana Yekona" yeKuchinjika kune Yakaoma Mamiriro

Kemikari reagents senge maajenti ekuchenesa uye mafuta ekuzora anowanzo shandiswa mumashopu ekuongorora ndege. Aluminium alloy mapuratifomu anowanzoita ngura, uye mapuratifomu esimbi anokandwa anogona zvakare kukanganiswa mukurongeka nekuda kweoxidation uye ngura. Granite inonyanya kuumbwa nemaminerari akadai sequartz uye feldspar. Iyo ine yakagadzikana makemikari zvimiro, pH kushivirira huwandu hwe1 kusvika 14, uye inogona kuramba kukukurwa kwezvinhu zvakajairika makemikari zvinhu. Iko hakuna simbi ion kunaya pamusoro payo, kuve nechokwadi chekutarisa yakachena nharaunda uye kudzivirira kuyerwa kukanganisa kunokonzerwa nekusvibiswa kwemakemikari. .

V. Machining Kururama: Iyo "Ideal Base" yekuyera Kwazvo

Kuburikidza neakanyanya-chaiyo tekinoroji senge magnetorheological polishing uye ion danda kugadzirisa, mapuratifomu egranite anogona kuwana kurongeka kwe + ± 0.1μm/m kwekupfava uye Ra≤0.02μm yekushata kwepamusoro, inopfuura nekure iyo yemapuratifomu esimbi yakakandwa (± 1μm/m yekufuratira) uye aruminiyamu yakati sandara/2m aruminiyamu. Iyi yepamusoro-chaiyo yepamusoro inopa chaiyo yekumisikidza referensi yepamusoro-chaiyo sensors uye kuyerwa probes, kufambisa kuzadzikiswa kweatatu-dimensional contour kuyerwa kweaero-injini blades padanho re0.1μm. .

Mumamiriro epamusoro anodiwa einjini yekuongorora blade, mapuratifomu egranite, ane mabhenefiti akazara mukudzikama kwemafuta, vibration kuramba, kuomarara, kugadzikana kwemakemikari uye kunyatsoita basa, yave sarudzo yakanakisa yekuve nechokwadi chekuongorora uye kuvimbika, nekuisa hwaro hwakasimba hwekugadzirwa kwemhando yepamusoro.

Nguva yekutumira: May-22-2025