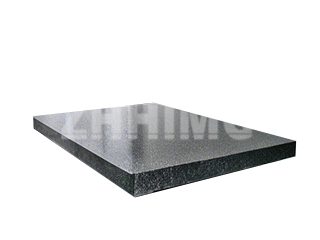

Mukutsvaga ma microchips madiki, anokurumidza, uye ane simba, zvinodiwa paWafer Processing Equipment zviri kuwedzera kusvika padanho rekururama raimboonekwa serisingawanikwe. Sezvo zvinhu zvichiderera kusvika munzvimbo ye nanometer ine nhamba imwe chete, kugadzikana kwepuratifomu yese yekugadzira kunova chinhu chakakosha. Pano, pasi pemhando dzakasiyana dze lasers, vacuum chambers, uye robotic systems, ndipo pane zvinhu zvekare—granite yechisikigo—zvinobuda sechinhu chakakosha chekubudirira kwema semiconductor emazuva ano. Magadzirirwo, mainjiniya, uye kuwanikwa kwezvikamu zvegranite zveOEM zvakanyatsonaka uye mubhedha we granite weOEM chete hazvisi zvehunyanzvi chete; ndizvo zvinosimbisa kushanda zvakanaka.

Basa remuchina mune chero sisitimu yakanyatsogadzirwa nderekupa nzvimbo yekutarisisa isingachinji uye yakagadzikana. Munzvimbo inoshanduka uye ine kurongeka-kukosha kwekugadzirwa kwesemiconductor, uko maitiro akadai se lithography, etching, uye deposition anoitika, kutsauka kudiki-kunyangwe padanho re sub-micron-kunogona kutungamira mukurasikirwa kukuru kwegoho. Sarudzo yezvinhu zvekutanga zvekuvaka, senge Wafer Processing Equipment machine base, saka idanho risingakurukurwe mukugadzira.

Mabhenefiti Echisikigo eGranite

Sei granite yechisikigo ichibudirira kupfuura zvinhu zvakagadzirwa neinjiniya zvakaita sesimbi yakakandwa, simbi, kana zvimwe zvinhu zvakagadzirwa neunyanzvi mukushandiswa uku kwakakosha? Mhinduro yacho iri muhunhu hwayo hwakasiyana, hwekare hwakakodzera nzvimbo isingakanganwiki yemichina yakanyatsogadzirwa.

1. Kuderedza Kudengenyeka Kwekutedzemuka Kunoshamisa (Kuparadzaniswa neMaitiro Ekuita):

Kudedera ndiyo muvengi wekugadzirwa kwe nanoscale. Ingave yakagadzirwa mukati memota nezvikamu zvinofamba kana kubva kunze kubva pasi peimba yekugezera, chero kutenderera kunofanirwa kunyudzwa nekukurumidza. Granite ine damping coefficient yepamusoro-soro yemukati-iri nani kupfuura simbi. Izvi zvinoreva kuti simba remakanika rinopera nekukurumidza sekupisa, kudzivirira resonance uye kuona kuti maitiro akakosha anoitwa pachikuva chakamira zvechokwadi. Izvi zvakakosha pakuchengetedza nzvimbo chaiyo yepakati mu lithography yepamusoro kana kuona kuti zvinhu zvakafanana zvinobviswa panguva yekuronga kwemakemikari (CMP).

2. Kuwedzera kweThermal Near-Zero (Kuchengetedza Kurongeka Kwakakwana):

Midziyo yekugadzira maWafer inowanzo sanganisira kushanduka-shanduka kwetembiricha, kwese kuri kwemhepo uye kwemaitiro. Zvinhu zvesimbi zvinowedzera uye zvinopera zvakanyanya nekuchinja kwetembiricha, zvichikonzera kudonha kwekupisa uye kusarongeka kwemasisitimu e optical kana mechanical. Granite, kunyanya granite nhema, inoratidza coefficient yakaderera kwazvo yekuwedzera kwekupisa (CTE), inenge 3×10⁻⁶/℃. Kugadzikana uku kwekupisa kunoita kuti kururama kwemuchina wegranite nezvimwe zvikamu zvegranite zveOEM zvirambe zvakafanana, zvichideredza zvikanganiso zvekupisa uye zvinovimbisa kudzokorora kwekuyera pasi pemamiriro akasiyana-siyana.

3. Kusimba Kwekupedzisira uye Kuomarara:

Kuburikidza nehunyanzvi hwepamusoro hwekukwesha nekupukuta, granite yechisikigo inogona kuita kuti pamusoro payo pave pakadzikama zvichiyerwa muma microns - chinhu chakakosha chinodiwa panzvimbo dzinoshandiswa mukutonga kufamba kwakanyatsojeka. Uyezve, modulus yayo yeYoung's high inopa kuomarara kwakanyanya uye kwakasimba. Kuramba uku kutsauka pasi pemutoro kwakakosha, sezvo hwaro hunofanira kutsigira mota dzakakura, matanho, uye zvivakwa zvakaoma zveWafer Processing Equipment assembly pasina kuchinjika kunoyerwa, kunyangwe munzvimbo dzakakura.

Kugadzira Ramangwana: Zvikamu zveGranite zveOEM uye Kuungana Kwakaomarara

Mashandisirwo egranite mazuva ano anopfuura mapuratifomu ari nyore. Vagadziri vemazuva ano vetekinoroji yepamusoro vanoda zvikamu zvegranite zveOEM zvakaoma, zvakagadzirwa nemaoko. Izvi zvinogona kusanganisira magwara ekufambisa mweya, machuck akaomarara evacuum, zvinhu zve multi-axis stage, uye mabhuroko ekuisa ma lasers ne optics. Zvidimbu izvi zvinowanzogadzirwa ne magadzirirwo akaomarara e geometric, anosanganisira maburi akaboorwa ekufambisa waya, ma threaded inserts ekuisa, uye ma dovetails kana ma slots e mabearing systems.

Maitiro ekugadzira Wafer Processing Equipment akazara anotanga nemubhedha mukuru wegranite. Zvikamu zvegranite zvinotevera zvinobatanidzwa kana kubatanidzwa pairi uchishandisa epoxy-based compounds yepamusoro, danho rakakosha rinoita kuti chivakwa chose chishande sechinhu chimwe chete, chakafanana. Kubatanidzwa kunobudirira kunoda kutarisisa zvakadzama:

-

Kugadzirisa: Zvikamu zvinofanirwa kugadzirwa zvinoenderana nezvinodiwa nemutengi, kazhinji zvinosanganisira kubatanidzwa kwezvinhu zvisiri zvegranite zvakaita semitsetse inotonhodza uye masensa anopinda zvakananga muchimiro.

-

Kuvimbiswa Kwemhando Yezvinhu: Chikamu chimwe nechimwe chinoda kudzorwa kwakasimba kwemhando, kusanganisira kutwasuka, kutwasuka, uye kusimbiswa kwemativi ese uchishandisa maCMM nema laser interferometers, zvichiita kuti zvisangane neISO uye zviyero zvepasi rose zvemetrology nekururama.

-

Kudyidzana Kwevatengesi: Kusarudza mutengesi wezvikamu zvegranite zveOEM idyidzana. Zvinoda kunzwisisa kwakadzama kwekushandiswa kwesemiconductor, kugona kusarudza dombo risina kugadzirwa repamusoro-soro, uye kugona kugadzira michina nekubatanidza zvivakwa zvakaoma zvichienderana ne nanometer tolerances.

Mukupedzisa, kunyange zvazvo microchip yakagadzirwa iri hunyanzvi hwevanhu, kugadzirwa kwayo kunoenderana nekugadzikana kwakanyarara kunopihwa nematombo echisikigo. Kushandiswa kwakasimba kwegranite sechinhu chikuru chemuchina wegranite uye zvimwe zvikamu zvegranite zveOEM zvakakosha chinhu chakakosha mukusundira miganhu ye miniaturization. Kune vagadziri veWafer Processing Equipment, kushanda pamwe chete nenyanzvi muzvivakwa zvegranite zvine hungwaru ndiyo danho rekutanga uye rakakosha rekuwana mukana wekukwikwidzana mumusika wepasi rose we semiconductor.

Nguva yekutumira: Zvita-01-2025